Sewing machines are incredibly easy tools that can be used to make a wide variety of garments and projects from just the tips of your finger. Why does sewing machine thread keep breaking

One of the most common problems when sewing is that the thread keeps breaking, which can be incredibly frustrating. Despite being a common issue, it does not have to be a problem if you understand why it happens and what steps you can take to prevent it from happening in the future here I will tell you how you can do that. In this article, we will talk about the best possible solution for Why does sewing machine thread keep breaking. This problem occurs with both thread breaking on industrial sewing machine and normal-use sewing machines.

What is the reason for the thread to break

1. Thread breakage is usually caused by many issues, wrong thread tension, incorrect needle size, or poor machine maintenance, which can be fixed easily by hand, What is the reason for the thread to break? If your thread tension is too loose or too tight, then this could cause the thread to break more often than usual as your machine will struggle with pulling the material through at an even rate.

Incorrect needle size can also cause similar issues with tension as well as damage to both your fabric and needle causing them to become weak over time and eventually snap while stitching. Finally, poor machine maintenance such as not regularly oiling your machine can create friction between mechanical parts. when Why does sewing machine thread keep breaking issue comes mostly after a few times this issue brings forth many other maintenance problems as well.

2. One reason why threads break is due to mechanical damage or abrasion. This damage happens when the threads get caught on something like an object or fabric while being woven into a material. This can cause fraying or tearing of the thread which will weaken it over time and eventually lead it to break. To prevent this type of damage, make sure that you are careful when weaving your thread into any materials and be extra cautious not to snag them.

3. Excessive force is perhaps the number one cause of thread breakage. When too much tension or pressure is applied to a thread during assembly or operation, it can lead to permanent damage and failure. This is especially true when using bolts or screws; if you apply too much torque when fastening them in place, it can lead to deformation and fracture of the threads.

4. These are the reason thread keeps breaking in the sewing machine. To avoid thread breakage is to select the correct type of thread for the project. Depending on the material being sewn, different types of threads may be necessary. For example, cotton or polyester are often used to stitch fabrics such as denim or corduroy while polyester-wrapped poly core threads are most often used to embroider on fine fabrics such as linen or silk. It’s also part of Why does sewing machine thread keep breaking.

Why does my top thread keep breaking

If you’re experiencing issues about Why does sewing machine thread keep breaking then you’re maybe as well experiencing issues with your top thread breaking on your sewing machine, it can be a frustrating and time-consuming problem to solve. However, why does my top thread keep breaking? There are a few common causes of this issue that can be easily identified and fixed. Here are some potential reasons why your top thread may keep breaking. “sewing top thread keeps breaking”

1. Tension too tight or too loose:

One of the most common causes of top thread breaking is an incorrect tension setting. If the tension is too tight, it can cause the top thread to snap under the pressure of the machine. Similarly, if the tension is too loose, the thread can get caught up and tangle, causing it to break. To fix this issue, try adjusting the tension dial to a lower or higher setting, depending on the problem.

2. Dirty or worn-out needle:

If the needle in your sewing machine is dirty or worn out, it can cause the top thread to break. Dirt, dust, and other debris can build up on the needle over time, making it less effective at piercing through the fabric. Similarly, a worn-out or damaged needle can cause the thread to snap or shred. To fix this issue, try replacing the needle with a new one and make sure to keep it clean and well-maintained.

3. Incorrect threading:

Another potential cause of a top thread breaking is incorrect threading of the machine. If the thread is not correctly threaded through the machine, it can get tangled or caught up, causing it to break. Make sure to follow the threading instructions in your sewing machine manual carefully, and double-check that the thread is correctly threaded through all of the necessary guides and tension disks.

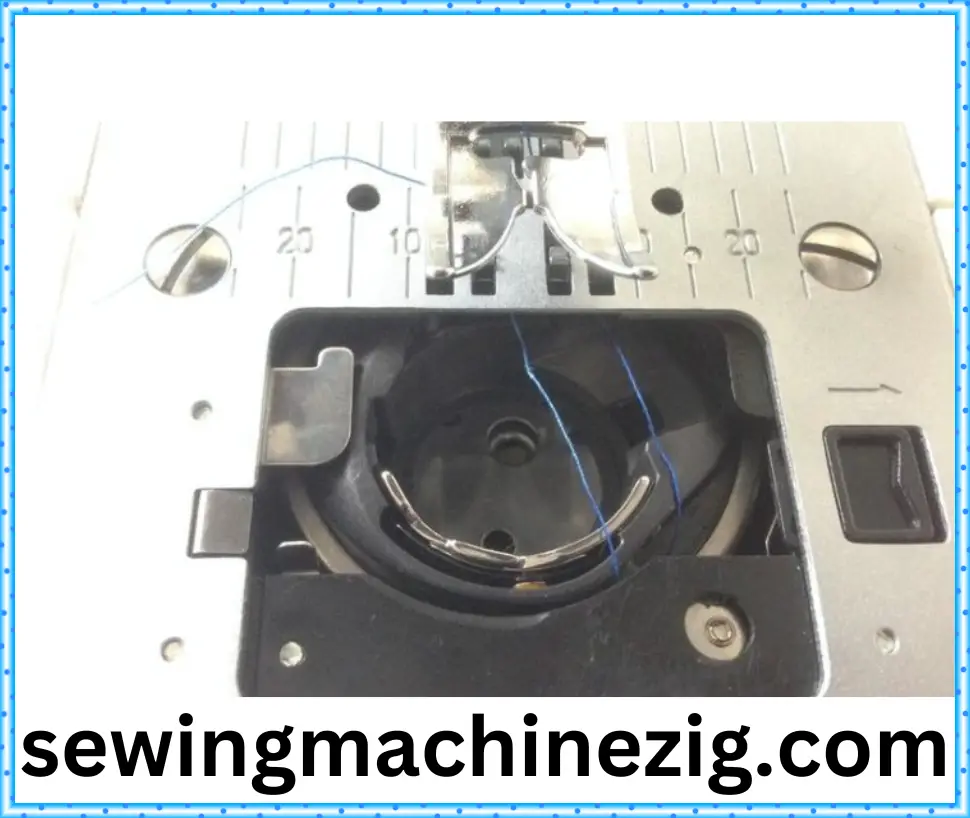

4. Bobbin issues:

Issues with the bobbin can also cause the top thread to break. If the bobbin tension is too tight or too loose, it can affect the way the top thread is pulled through the fabric, causing it to break. Additionally, if the bobbin is not wound correctly or is inserted incorrectly into the machine, it can cause the top thread to tangle or snap. To fix this issue, make sure to properly wind and insert the bobbin and adjust the bobbin tension as necessary.

5. Fabric type or thickness:

Finally, the type or thickness of the fabric you are working with can also affect the top thread. If the fabric is too thick, the thread may not be able to pass through it effectively, causing it to break. Similarly, if the fabric is too thin or delicate, the thread may be more likely to snag or tangle, leading to breakages. To avoid this issue, try adjusting your needle and thread size to better match the fabric you are working with. I hope now you are aware of how to handle the problem of Why does sewing machine thread keep breaking.

Why does my sewing machine Bobbin thread keep breaking

I hope now you Know well Why does sewing machine thread keep breaking. A sewing machine is a fantastic tool for sewing various fabrics and creating stunning designs. However, if you are experiencing issues with your bobbin thread breaking, it can be frustrating and can slow down your sewing process. Here are some of the reasons why your sewing machine bobbin thread may keep breaking, “thread breaking sewing machine”:

1. Incorrect Bobbin Size:

“Sewing machine thread breaking” One of the most common reasons for a broken bobbin thread is using the wrong size bobbin. Using the incorrect bobbin size can cause the thread to bunch up, leading to tension issues, needle breaks, and even bobbin thread breakage. Before starting your project, make sure you are using the right bobbin size.

2. Poor Bobbin Quality:

The quality of the bobbin can also cause breakage issues. Poor-quality bobbins tend to warp and damage quickly, leading to bobbin thread breakage. Consider investing in high-quality bobbins that are compatible with your sewing machine for smooth operation.

3. Tension Problems:

Incorrect tension settings can cause bobbin thread breakage. If the bobbin thread is not evenly wound, the top and bottom threads will not interlock correctly, leading to tension problems. Check your tension settings and adjust accordingly for a smooth and even stitch.

4. Bobbin Winding Issues:

If the bobbin is not wound correctly, it can lead to thread breakage. The thread should be wound evenly and tightly, with no loose or skipped sections. Improper winding can cause the thread to bunch up, leading to breakage.

5. Thread Quality:

Using poor-quality thread can cause the bobbin thread to break frequently. Low-quality threads tend to shred and break, leading to tension issues and ultimately bobbin thread breakage. Consider using high-quality thread for the best results.

6. Bobbin Placement:

If the bobbin is not placed correctly, it can cause the thread to break. Ensure the bobbin is placed correctly in the bobbin case and threaded correctly through the machine for smooth operation. I hope now you Know well Why does sewing machine thread keep breaking.

Why do my sewing needles keep breaking

when Sewing needles are an essential part of a sewing machine, and they can break due to various reasons? Needle breakage can be frustrating and can slow down your sewing progress, but it can be avoided by identifying the reasons for the breakage. Here are some of the most common reasons why sewing needles keep breaking also called sewing machine thread keeps breaking.

1. Dull Needles:

Sewing needles can become dull after prolonged use, which can cause them to break. Dull needles have difficulty piercing through fabrics, leading to increased friction, which can result in needle breakage. It is essential to change your sewing machine needles regularly to prevent dullness.

2. Incorrect Needle Type:

Using the wrong type of needle for the fabric can cause it to break. Different types of needles have specific purposes, and using the wrong type can cause unnecessary stress on the needle, leading to breakage. Ensure you choose the correct needle type for your fabric to prevent breakage.

3. Bent Needles:

Bent needles can break easily while sewing. Bent needles can be caused by hitting pins, pulling the fabric while sewing, or improper installation of the needle. Ensure the needle is installed correctly, and avoid hitting pins while sewing.

4. Incorrect Needle Size:

Using the wrong needle size can also cause breakage. The needle size depends on the fabric type and thickness. Using a needle that is too small for the fabric can cause breakage because it can bend and break under the stress of sewing.

5. Fabric Quality:

Some fabrics can be tough and cause needles to break quickly. Fabrics like leather, denim, and canvas require thicker needles and can cause stress on the needles, leading to breakage. Always use the correct needle size and type for the fabric you are working on.

6. Sewing Techniques:

Improper sewing techniques, like sewing too fast or pulling the fabric, can cause needle breakage. Always sew at a steady pace and avoid pulling the fabric, which can cause the needle to bend or break thread on the sewing machine. These all were the top best solution to Why does sewing machine thread keep breaking.

What is Thread In Sewing Machine?

Thread in a sewing machine is like the magic ingredient that holds everything together. It’s basically a thin, long strand of material, usually made of cotton, polyester, or a blend of both. Think of it as the glue that stitches your fabric pieces together.

When you load the thread into the sewing machine, it travels through various parts of the machine, like the tension discs and the needle, before looping around the bobbin thread to create stitches. The type of thread you use can affect the strength and appearance of your stitches, so it’s important to choose the right one for your project.

Thread comes in all sorts of colors, thicknesses, and materials, so you can really get creative with your sewing projects. Plus, having a good quality thread can make a big difference in how smoothly your sewing machine operates and how durable your finished piece is. So, next time you’re sewing, remember to give a little credit to the humble thread for keeping everything together!

Why Is Thread Important For Sewing Machine?

Thread is like the lifeblood of a sewing machine. It’s crucial for several reasons.

Firstly, without thread, the sewing machine wouldn’t be able to create stitches. Thread is what forms the interlocking loops that bind fabric together, turning separate pieces into a cohesive whole.

Secondly, the quality and type of thread used can significantly impact the strength and appearance of the stitches. Using the right thread for the job ensures that your seams hold up under stress and that your finished piece looks neat and professional.

Additionally, thread plays a key role in the overall functioning of the sewing machine. It needs to be correctly loaded and threaded through various components like the tension discs and the needle for the machine to operate smoothly and produce consistent stitches.

In essence, thread is not just important but absolutely essential for a sewing machine to fulfill its purpose of joining fabric together effectively and efficiently.

What Is Upper Thread In Sewing Machine

The upper thread in a sewing machine refers to the thread that runs from the spool, through various threading paths and tension mechanisms, and finally through the needle. It’s the thread that forms the top portion of the stitch when sewing.

When you’re using a sewing machine, the upper thread is typically wound around a spool located on the top of the machine. From there, it travels through a series of guides and tension discs, which help control the tension of the thread as it’s fed into the machine. Finally, the upper thread passes through the eye of the needle, where it’s then pulled down into the fabric to create stitches.

The upper thread works in conjunction with the bobbin thread, which is the thread wound on a small spool underneath the needle plate. Together, these two threads form the stitches that join pieces of fabric together when sewing with a machine.

What Is Thread Quality In Sewing Machine

Thread quality in sewing machine refers to the characteristics of the thread used for stitching in terms of its strength, durability, smoothness, and consistency. Here’s why it matters:

- Strength: High-quality thread is strong and can withstand the stress of sewing without breaking. This is particularly important for seams that will be subject to tension or wear, ensuring they hold up over time.

- Durability: Thread quality affects how well the stitches hold together over time and through washings or regular use. A good-quality thread will resist fraying and weakening, contributing to the longevity of the garment or project.

- Smoothness: Smooth thread runs through the machine more evenly, reducing the likelihood of snags, tangles, or thread breakage. It also contributes to the neatness and consistency of the stitches.

- Consistency: Consistent thread thickness and texture ensure uniform stitches throughout the sewing process. Inconsistent thread can result in irregular tension or stitch formation, leading to poor-quality seams or even machine jams.

Choosing the right thread quality for your sewing project is essential for achieving professional-looking results and ensuring the durability of your finished piece. Higher-quality threads may cost more initially, but they often pay off in terms of improved sewing performance and the longevity of your creations.

Why Does Bobbin Thread Break

Bobbin thread breakage can be frustrating, but it usually happens for a few common reasons:

- Incorrect Tension: If the tension on your bobbin thread is too tight or too loose, it can cause the thread to break. Check your sewing machine’s manual for guidance on adjusting bobbin tension, and make sure the thread is properly threaded through the tension mechanism.

- Thread Quality: Low-quality or old thread can be prone to breakage. Ensure you’re using a good-quality bobbin thread that’s suitable for your sewing project. Also, check if the thread is tangled or has any knots that could cause it to break.

- Bobbin Winding: If the bobbin is wound unevenly or too tightly, it can cause the thread to break as it feeds through the machine. Make sure the bobbin is wound smoothly and evenly, without any gaps or overlaps in the thread.

- Machine Maintenance: A dirty or poorly maintained sewing machine can contribute to bobbin thread breakage. Regularly clean and oil your machine according to the manufacturer’s instructions to ensure smooth operation.

- Needle Issues: A dull or damaged needle can snag the bobbin thread as it passes through the fabric, leading to breakage. Replace the needle regularly, especially if you’re working with heavy or thick fabrics.

- Fabric or Needle Choice: Certain fabrics or needle types may not be compatible with the bobbin thread you’re using, leading to breakage. Experiment with different needle sizes and types to find the best match for your project.

By troubleshooting these common issues, you can often prevent bobbin thread breakage and enjoy smoother sewing sessions.

Can Needle Force Sewing Machine Thread To Break

Yes, the needle can indeed contribute to sewing machine thread breakage. Here’s how:

- Needle Damage: A dull or damaged needle can cause the thread to break. When the needle is dull, it can snag or shred the thread as it pierces through the fabric. Similarly, if the needle has a burr or a rough spot, it can damage the thread as it passes through the eye of the needle.

- Wrong Needle Size: Using the wrong needle size for your fabric can also lead to thread breakage. If the needle is too large for the thread or fabric, it can create large holes that weaken the thread. Conversely, if the needle is too small, it can cause the thread to fray or break as it struggles to pass through the fabric.

- Needle Position: Sometimes, the needle may not be properly inserted into the needle clamp or may not be fully seated in the needle bar. This misalignment can cause the needle to deflect or hit the throat plate, resulting in thread breakage.

- Needle Type: Using the wrong type of needle for your fabric can also lead to thread breakage. For example, a ballpoint needle is designed for knit fabrics and may not be suitable for woven fabrics, leading to thread breakage.

By ensuring that your needle is in good condition, properly sized, correctly inserted, and appropriate for your fabric, you can help prevent thread breakage and enjoy smoother sewing.

Conclusion

I hope that now you are well aware of Why does sewing machine thread keep breaking. By identifying and addressing Why does sewing machine thread keep breaking and the root causes of thread breakage, such as using the wrong needle, incorrect tension settings, and improper threading, sewers can avoid frustrating and time-consuming thread breakage and create beautiful and successful sewing projects. I hope after reading this article and applying the changes your problem about Why does sewing machine thread keep breaking resolve.

FAQs

Why does my sewing machine thread keep breaking on my industrial sewing machine?

Possible reasons for thread breakage on an industrial sewing machine include improper tension, a dull needle, incorrect thread, or machine malfunction.

Why does my thread keep breaking on my Janome sewing machine?

Possible reasons for thread breakage on a Janome sewing machine include incorrect threading, poor quality thread, a damaged needle, or machine malfunction.

Sewing machine’s top thread keeps breaking?

Possible reasons for the top thread keeps breaking on a sewing machine include incorrect threading, poor quality thread, incorrect tension, a damaged needle, or machine malfunction.

Why does my thread keep breaking on my brother’s sewing machine?

Possible reasons for thread breakage on a Brother sewing machine include incorrect threading, poor quality thread, incorrect tension, a damaged needle, or machine malfunction.

Does thread keep breaking on a Singer sewing machine?

Possible reasons for thread breakage on a Singer sewing machine include incorrect threading, poor quality thread, incorrect tension, a damaged needle, or machine malfunction.

Why does my thread keep breaking on my sewing machine?

Possible reasons for thread breakage on a sewing machine include incorrect threading, poor quality thread, incorrect tension, a damaged needle, or machine malfunction.