By Delving into the world of sewing machines reveals a fascinating array of designs, each with unique features. For those exploring this realm, the question often arises: “What is a low shank sewing machine?” This inquiry opens a door to understanding the mechanical nuances that distinguish low shank models.

In this exploration, we demystify the concept, unraveling the significance of the low shank design and its impact on your sewing endeavors.

Join us as we delve into the intricacies of sewing machine anatomy, shedding light on the low shank’s role in enhancing versatility and precision.

What Is A Low Shank Sewing Machine Detailed Answer

Unveiling the Mechanism: What Is a Low Shank Sewing Machine? A Comprehensive Exploration

The world of sewing machines is a vast landscape, and for both beginners and seasoned sewists, understanding the nuances of machine types is paramount.

In this extensive exploration, “What is a low shank sewing machine” we delve into the intricate details of “What Is a Low Shank Sewing Machine?” This comprehensive guide aims to demystify the concept, providing a step-by-step journey through the anatomy, functionality, and advantages of low-shank sewing machines.

Understanding the Basics: What Is a Shank in a Sewing Machine?

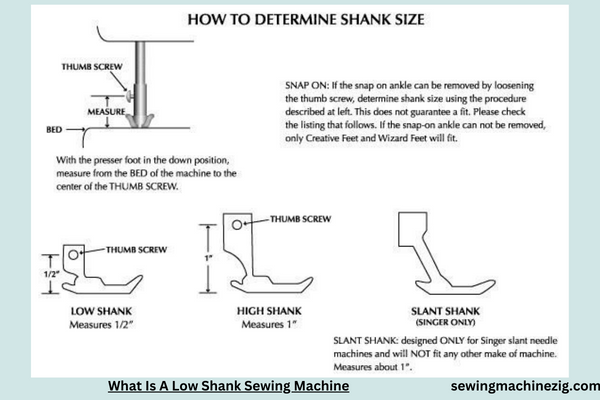

Before we delve into the specifics of low shank machines, let’s establish a fundamental understanding of what a shank is in the context of sewing machines. The shank refers to the part of the machine that holds the needle. It is a crucial component that influences the machine’s compatibility with different presser feet and accessories.

Step 1: Identifying the Shank Types

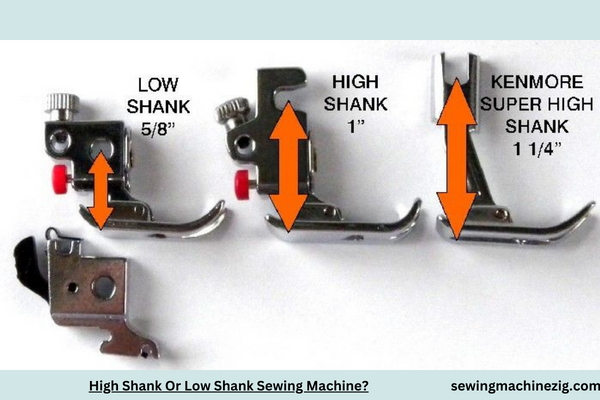

Sewing machines generally fall into three shank categories: high shank, low shank, and slant shank. Each type dictates the compatibility of presser feet and accessories that can be used with the machine. In this guide, our focus is on the low shank variety.

Step 2: Defining the Low Shank Sewing Machine

A low shank sewing machine is characterized by a shorter distance between the bottom of the presser foot holder and the needle plate. This shorter shank makes low shank machines versatile and widely compatible with a diverse range of presser feet and attachments.

Step 3: Examining the Anatomy of a Low Shank Machine

To identify a low shank sewing machine, examine the distance between the needle plate and the bottom of the presser foot holder. In a low shank machine, this distance is typically around ½ inch (13 mm) or less. This design facilitates easier attachment of various presser feet, allowing sewists to explore different techniques and applications.

Step 4: Advantages of Low Shank Sewing Machines

Now that we have a clear understanding of what constitutes a low shank sewing machine, let’s explore the advantages that come with this design.

Advantage 1: Versatility in Presser Feet

One of the primary advantages of low shank machines is their compatibility with a vast array of presser feet. From basic straight stitch feet to specialized feet for quilting, embroidery, and zipper installation, low shank machines provide sewists with the flexibility to tackle diverse projects.

Advantage 2: Access to Specialty Feet

Low shank machines open the door to a world of specialty presser feet. Attachments for piping, cording, and even free-motion quilting can be easily incorporated into your sewing repertoire. The ability to switch between feet seamlessly enhances creativity and precision in various sewing applications.

Advantage 3: Ease of Attachment and Removal

The design simplicity of low shank machines makes attaching and removing presser feet a straightforward process. This ease of use is particularly beneficial for sewists who frequently switch between different feet for varied projects.

Advantage 4: Cost-Effective Flexibility

Low shank sewing machines offer a cost-effective solution for sewists seeking versatility in their projects. Instead of investing in multiple machines for specific tasks, a low shank machine allows users to adapt their existing equipment to a wide range of applications.

Step 5: Compatible Accessories and Attachments

To fully leverage the advantages of a low shank sewing machine, explore the plethora of accessories and attachments available. From walking feet for even fabric feeding to quilting guides and edge-stitching feet, the compatibility of low shank machines extends to an extensive range of tools that enhance your sewing experience.

Step 6: Choosing the Right Presser Foot

When working with a low shank machine, selecting the appropriate presser foot for your project is crucial. Whether you’re engaging in delicate embroidery, precise topstitching, or quilting, having the right foot ensures optimal results. Consult your machine’s manual for guidance on compatible feet and their recommended uses.

Step 7: Exploring Specialty Techniques

With the versatility afforded by a low shank sewing machine, it’s time to explore specialty techniques. Delve into the world of free-motion quilting, experiment with intricate embroidery patterns, or master the art of attaching zippers with ease. The compatibility of various presser feet empowers you to push the boundaries of your sewing skills.

Step 8: Maintenance and Care

To ensure the longevity and optimal performance of your low shank sewing machine, incorporate regular maintenance into your sewing routine. Clean the machine regularly, change needles as needed, and follow the manufacturer’s guidelines for lubrication. Well-maintained machines deliver consistent results and minimize the risk of issues.

Step 9: Troubleshooting Tips

If you encounter any issues with your low shank sewing machine, consult the troubleshooting section of your machine’s manual. Common issues such as thread tension problems or stitching irregularities often have straightforward solutions outlined in the manual. Addressing issues promptly enhances the overall sewing experience.

Step 10: Upgrading Your Sewing Arsenal

As your skills and projects evolve, you may find the need to explore additional presser feet and attachments. Consider expanding your collection to include feet for specific tasks, such as gathering, hemming, or creating decorative stitches. The versatility of low shank machines allows you to continually enhance your sewing capabilities.

Unleashing Creativity with Low Shank Precision

In summary, understanding “What is a low shank sewing machine” opens the door to a world of sewing possibilities. The versatility, compatibility, and ease of use offered by low shank machines empower sewists to unleash their creativity with precision.

Whether you’re a quilting enthusiast, an embroidery artist, or a versatile seamstress, the low shank sewing machine is a valuable tool in your crafting arsenal. Explore, create, and sew with confidence, knowing that your low shank machine is designed to adapt to the ever-expanding landscape of your sewing journey. Happy stitching!

What Is A Low Shank Adapter

Decoding Sewing Machine Compatibility: What Is a Low Shank Adapter and How to Use It Effectively

In the vast world of sewing machines and accessories, understanding the intricacies of compatibility is key to unlocking the full potential of your equipment. One crucial tool that often comes into play is the “Low Shank Adapter.” In this comprehensive guide, we will unravel the mysteries surrounding the low shank adapter, exploring its purpose, functionality, and step-by-step instructions on how to use it effectively.

Understanding the Basics: What Is a Low Shank Adapter?

Before we delve into the specifics, let’s establish a foundational understanding of what a low shank adapter is. In sewing machine terminology, the shank refers to the part of the machine that holds the needle. The shank type determines the compatibility of presser feet and accessories with the machine.

A low shank adapter is a clever accessory designed to modify the shank height of a sewing machine, effectively converting it from a high shank to a low shank configuration. This adaptation is particularly useful when you have a low shank presser foot or attachment that you want to use on a high shank machine.

Step 1: Identifying Your Sewing Machine Shank Type

The first step in the process is to identify the shank type of your sewing machine. As mentioned earlier, sewing machines generally fall into three shank categories: high shank, low shank, and slant shank. Consult your sewing machine’s manual or do a quick online search for your machine model to determine its shank type.

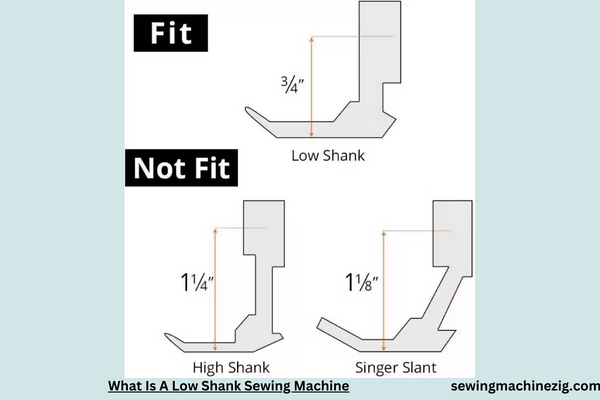

Step 2: Understanding High Shank vs. Low Shank Machines

High shank machines have a larger distance between the bottom of the presser foot holder and the needle plate, typically around 1¼ inches (32 mm) or more. Low shank machines, on the other hand, have a shorter distance, usually around ½ inch (13 mm) or less. It’s essential to know your machine’s shank type to ensure compatibility with presser feet and accessories.

Step 3: Recognizing the Need for a Low Shank Adapter

The need for a low shank adapter arises when you have a low shank presser foot or attachment that you want to use on a high shank machine. Instead of investing in a separate low shank machine, the adapter provides a cost-effective solution to make your high shank machine versatile and compatible with a broader range of accessories.

Step 4: Acquiring a Compatible Low Shank Adapter

Before acquiring a low shank adapter, ensure compatibility with your specific sewing machine model. Adapters come in various designs, and some may have additional features, such as adjustable height settings. Choose an adapter that aligns with your machine’s specifications for optimal performance.

Step 5: Installing the Low Shank Adapter

Now that you have your low shank adapter, it’s time to install it on your sewing machine. Follow these steps for a seamless installation:

a. Turn off your sewing machine and unplug it for safety.

b. Remove the presser foot currently attached to your machine.

c. Loosen the screw that holds the presser foot holder in place.

d. Carefully slide the low shank adapter onto the presser bar.

e. Tighten the screw to secure the adapter in place.

Step 6: Attaching Low Shank Presser Feet

With the low shank adapter successfully installed, you can now attach low shank presser feet and accessories to your high shank sewing machine. Here’s how:

a. Select the low shank presser foot or attachment you want to use.

b. Place the foot or attachment under the presser foot holder.

c. Lower the presser foot holder, ensuring that the foot or attachment is securely in place.

d. Tighten the presser foot screw to hold the foot or attachment firmly.

Step 7: Testing the Compatibility

Before diving into your project, perform a test run to ensure that the low shank adapter and presser foot are compatible with your high shank machine. Stitch on a scrap piece of fabric to check for smooth operation, even stitches, and proper functionality of the presser foot or attachment.

Step 8: Exploring Versatility with Low Shank Accessories

Now that your high shank machine is equipped with a low shank adapter, you gain access to a broader range of presser feet and accessories. Explore the versatility offered by low shank attachments, such as walking feet for even fabric feeding, quilting feet for intricate quilting designs, and zipper feet for precise zipper installation.

Step 9: Adapting to Changing Sewing Needs

The beauty of the low shank adapter lies in its adaptability to changing sewing needs. As you progress in your sewing journey and explore new techniques, having a versatile machine equipped with a low shank adapter ensures that you can readily adapt to the demands of different projects without the need for multiple machines.

Step 10: Maintaining Your Low Shank Adapter

To ensure the longevity and optimal performance of your low shank adapter, incorporate regular maintenance into your sewing routine. Clean the adapter, check for any signs of wear or damage, and follow the manufacturer’s guidelines for lubrication if applicable. A well-maintained adapter contributes to a smooth sewing experience.

Step 11: Troubleshooting Tips

If you encounter any issues with your low shank adapter, consult the troubleshooting section of the adapter’s manual. Common issues such as difficulty attaching presser feet, uneven stitches, or instability can often be addressed with simple adjustments. Prompt troubleshooting enhances your overall sewing experience.

Step 12: Upgrading Your Sewing Arsenal

As you become more proficient in your sewing skills and take on diverse projects, you may find the need to expand your collection of presser feet and accessories. Invest in high-quality low shank attachments to further enhance your sewing capabilities. Whether you’re delving into intricate embroidery or tackling challenging fabrics, having the right tools at your disposal is essential.

Elevating Your Sewing Experience with a Low Shank Adapter

In conclusion, understanding “What Is a Low Shank Adapter” is a gateway to unlocking the full potential of your sewing machine. This versatile accessory empowers you to bridge the compatibility gap between high shank machines and low shank accessories, providing a cost-effective solution to adapt to changing sewing needs.

Follow the step-by-step guide outlined in this comprehensive exploration, and elevate your sewing experience with the flexibility and versatility offered by a low shank adapter. Happy sewing!

High Shank Or Low Shank Sewing Machine?

In the realm of sewing machines, the decision between a high shank or low shank configuration is a pivotal factor that can significantly impact your sewing experience.

In this in-depth guide, we will unravel the intricacies of “High Shank or Low Shank Sewing Machine,” providing a step-by-step exploration to help you make an informed decision based on your preferences, projects, and sewing aspirations.

Understanding the Basics: What Is Shank Height in a Sewing Machine?

Before delving into the high shank vs. low shank debate, let’s establish a foundational understanding of what shank height means in the context of a sewing machine. The shank is the part of the machine that holds the needle. Shank height refers to the distance between the bottom of the presser foot holder and the needle plate.

Step 1: Identifying High Shank Machines

High shank sewing machines are characterized by a larger distance between the presser foot holder and the needle plate. Typically, this distance measures around 1¼ inches (32 mm) or more. High shank machines are often associated with industrial or heavy-duty models designed for specific applications.

Step 2: Recognizing Low Shank Machines

Conversely, low shank sewing machines have a shorter distance between the presser foot holder and the needle plate, usually around ½ inch (13 mm) or less. Low shank machines are known for their versatility and compatibility with a wide range of presser feet and accessories.

Step 3: Evaluating Your Sewing Needs and Projects

The choice between a high shank and low shank machine often boils down to your specific sewing needs and the projects you plan to undertake. Consider the following factors:

a. Project Types: If you predominantly engage in general sewing, quilting, or crafting, a low shank machine may offer the versatility needed for diverse projects.

b. Specialized Applications: For specialized applications like embroidery or heavy-duty sewing, a high shank machine may be better suited to handle the demands of these tasks.

Step 4: Exploring Presser Foot Compatibility

The compatibility of presser feet and accessories is a critical aspect to consider when deciding between a high shank or low shank machine.

a. High Shank Machines: These machines often require presser feet designed specifically for high shank configurations. Specialized feet for tasks like quilting, piping, and cording are available for high shank machines.

b. Low Shank Machines: Low shank machines offer a broader range of presser feet options. From basic straight stitch feet to intricate embroidery feet, low shank machines provide versatility for various applications.

Step 5: Assessing Machine Availability and Models

The availability of high shank or low shank models depends on the brand and type of sewing machine you are considering. Research and compare different models within your preferred brand to determine which shank configuration aligns with your sewing preferences.

Step 6: Exploring Sewing Machine Brands and Models

Different sewing machine brands may have varying shank configurations within their product lines. Explore popular brands and models to find one that suits your specific requirements. Consider factors such as brand reputation, features, and user reviews when making your decision.

Step 7: Investigating Sewing Machine Attachments and Accessories

In addition to presser feet, consider the availability of other attachments and accessories for your chosen shank configuration.

a. High Shank Accessories: High shank machines may offer accessories tailored to specific tasks, such as walking feet for even fabric feeding or quilting feet for intricate quilting designs.

b. Low Shank Accessories: Low shank machines provide a wide array of accessories, including embroidery feet, zigzag feet, and open toe feet for improved visibility during stitching.

Step 8: Consult Your Sewing Machine Manual

Your sewing machine’s manual is a valuable resource for understanding its shank configuration and recommended accessories. Refer to the manual for information on presser feet, maintenance guidelines, and any specific considerations related to the shank type.

Step 9: Testing and Trying Machines In-Store

If possible, visit a sewing machine retailer to test and try different models in-store. This hands-on experience allows you to feel the machine’s performance, evaluate its features, and assess its compatibility with your preferred presser feet and accessories.

Step 10: Considering Future Projects and Growth

When making the high shank vs. low shank decision, think about your long-term sewing goals and potential projects. If you anticipate delving into new techniques or expanding your sewing skills, a machine with the appropriate shank configuration can accommodate your evolving needs.

Step 11: Weighing the Cost and Investment

Evaluate the cost and investment associated with high shank and low shank machines. Consider not only the initial purchase price but also the long-term value, taking into account the versatility, accessories, and capabilities offered by each configuration.

Step 12: Making an Informed Decision

Armed with a thorough understanding of your sewing needs, preferences, and the characteristics of high shank and low shank machines, you can now make an informed decision. Whether you opt for the versatility of a low shank machine or the specialized capabilities of a high shank machine, your choice should align with your unique sewing journey.

Elevating Your Sewing Experience with the Right Shank Configuration

In summary, the high shank vs. low shank decision is a crucial aspect of selecting the perfect sewing machine for your needs. By following this comprehensive guide, you’ve gained insights into the considerations, steps, and factors that influence this choice.

Whether you’re drawn to the versatility of a low shank machine or the specialized capabilities of a high shank machine, your decision should ultimately enhance and elevate your sewing experience. Happy stitching!

Conclusion

In conclusion, unraveling the mystery of “What is a low shank sewing machine” sheds light on a fundamental aspect of sewing machine compatibility. Recognizing the significance of the shank type empowers sewists to select the right accessories and presser feet for optimal functionality. With this knowledge, navigating the vast world of sewing machine attachments becomes a seamless and informed journey.

Embrace the versatility of low-shank machines, ensuring your sewing endeavors are not only creative but also efficient and tailored to your specific machine’s requirements.

FAQs for “What Is A Low Shank Sewing Machine”

Q1: What does the term “low shank” mean in the context of sewing machines?

A1: “Low shank” refers to the position of the presser foot attachment on a sewing machine. It indicates that the machine uses low shank presser feet and accessories.

Q2: How can I identify if my sewing machine is a low shank model?

A2: Check the distance between the needle plate and the screw that holds the presser foot. If it’s around ½ inch, your machine likely has a low shank. “What is a low shank sewing machine“

Q3: Are low shank sewing machines suitable for all types of sewing projects?

A3: Yes, low shank machines are versatile and can handle various projects. They are commonly used for general sewing, quilting, and garment construction. “What is a low shank sewing machine“

Q4: Can I use high shank presser feet on a low shank sewing machine?

A4: No, presser feet are not interchangeable between high and low shank machines. Always use presser feet specifically designed for your machine’s shank type. “What is a low shank sewing machine“

Q5: Do low shank sewing machines have any advantages over other shank types?

A5: Low shank machines are often more common and have a wider variety of compatible accessories available, making them convenient for many sewists. “What is a low shank sewing machine“

Q6: Can I convert a low shank sewing machine to a high shank or vice versa?

A6: Generally, it’s not advisable to convert shank types. The design and mechanics of the machine are optimized for its specific shank configuration. “What is a low shank sewing machine“