In the world of sewing, bobbins are the unsung heroes that play a vital role in achieving smooth and balanced stitches. These small spools hold the lower thread, working in harmony with the upper thread from the sewing machine’s needle.

While often overlooked, how do bobbins work, here the mechanics of bobbins are fascinating and integral to the overall sewing process. A bobbin is a small cylindrical device, typically made of plastic or metal that holds the thread underneath the fabric being sewn.

It is placed in the bobbin case or bobbin holder, which is located below the sewing machine’s needle plate. how do bobbins work well as the upper thread passes through the needle, it interlocks with the thread from the bobbin, creating the stitch formation.

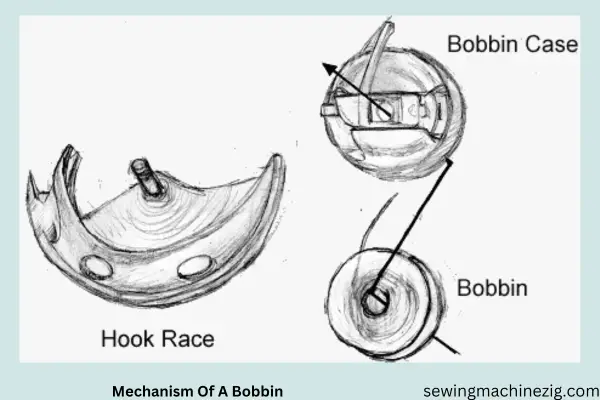

Mechanism Of A Bobbin

The key mechanism of a bobbin is its ability to rotate freely within the bobbin case. When the sewing machine is in operation of how do bobbins work, the bobbin rotates, unwinding the thread and allowing it to be pulled up through the fabric.

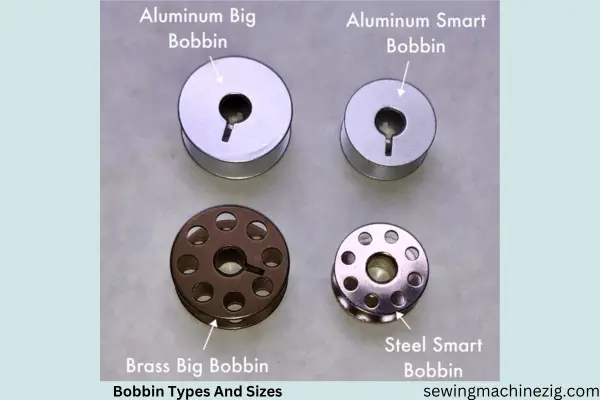

The tension applied to the thread on the bobbin affects the tightness and balance of the stitches. Bobbins come in different sizes and types, depending on the sewing machine model and the type of thread being used. Some bobbins are pre-wound, while others can be filled with thread manually using a bobbin winder.

Understanding how do bobbins work is crucial for achieving consistent stitch quality and preventing thread tangles or jams. The correct placement and tension of the bobbin thread contribute to the overall performance of the sewing machine and the appearance of the finished project.

In the following sections, we will delve deeper into the functionality of bobbins and learn how do bobbins work, explore different types and sizes, discuss the importance of proper tension, and provide practical tips for maintaining and troubleshooting bobbin-related issues.

Get ready to unravel the mysteries behind these tiny yet essential components of sewing machines.

Step-by-Step Guide:

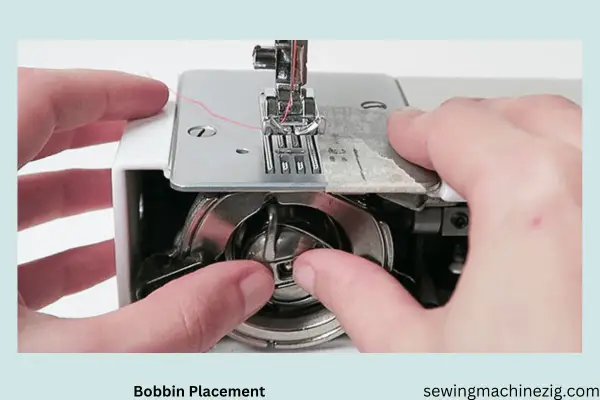

1. Bobbin Placement:

Bobbins are placed in the bobbin case or bobbin holder, which is located below the sewing machine’s needle plate. The bobbin sits horizontally in the case, allowing it to rotate freely during sewing.

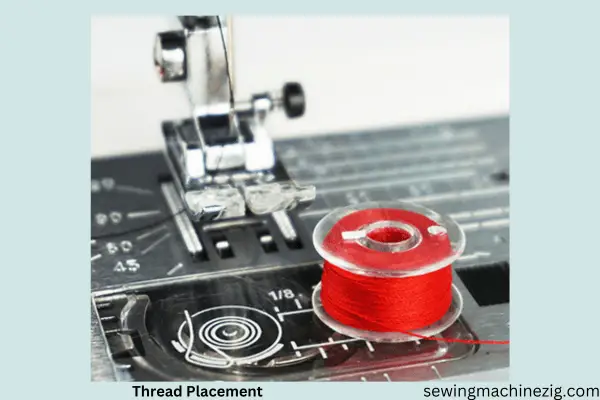

2. Thread Placement:

The thread from the bobbin is threaded through the bobbin case and extends out through a small slot or opening. This thread is known as the bobbin thread.

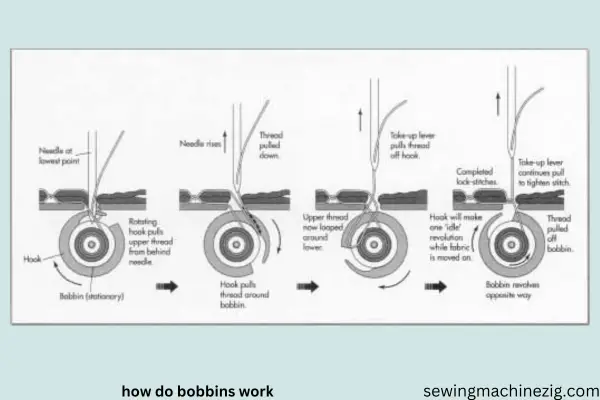

3. Interlocking Threads:

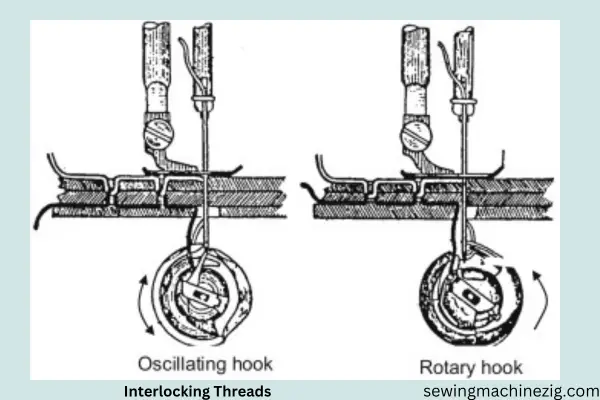

As you sew, the sewing machine’s needle passes through the fabric, creating a loop of the upper thread.

The needle then moves back up, and the hook or shuttle mechanism catches the loop of the upper thread and carries it around the bobbin case.

The bobbin thread, being pulled by the rotating bobbin, interlocks with the loop of the upper thread, forming a stitch.

4. Tension Control:

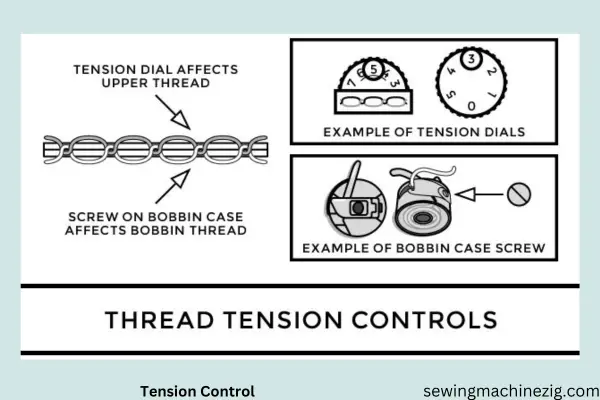

The tension of the bobbin thread is crucial for achieving balanced stitches. The bobbin case may have a small tension adjustment screw that allows you to regulate the tension of the bobbin thread.

Proper tension ensures that the upper and lower threads are evenly balanced, preventing loose or tight stitches.

5. Thread Supply:

As the upper thread continues to form stitches, the bobbin rotates and supplies a continuous feed of thread. The bobbin thread is drawn up through the fabric, creating the lower portion of the stitch.

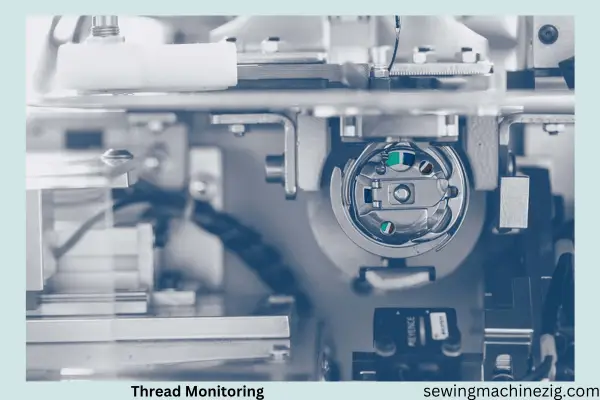

6. Thread Monitoring:

Some sewing machines have a transparent bobbin case or a window that allows you to monitor the amount of thread remaining on the bobbin. This enables you to anticipate when the bobbin needs to be refilled or replaced.

7. Bobbin Types And Sizes:

Bobbins come in various types and sizes, depending on the sewing machine model. It’s important to use the correct bobbin size and type specified by your machine’s manufacturer to ensure proper fit and function.

Understanding how do bobbins work and maintaining proper tension and thread supply is crucial for achieving high-quality stitches in your sewing projects. With practice and attention to detail, you can master the art of working with bobbins and produce professional-looking results.

Why Do You Need Bobbins?

Bobbins are a fundamental component in the sewing and textile industries, serving a crucial purpose in the stitching process. With their compact cylindrical design, bobbins play a significant role in thread storage, organization, and tension control. These small but mighty devices ensure that thread remains untangled, accessible, and neatly wound during sewing.

By integrating the bobbin’s lower thread with the upper thread from the spool, sewing machines create interlocked stitches, resulting in a wide range of fabric creations. Bobbins are essential tools for achieving consistent stitch quality, allowing sewing enthusiasts and professionals to bring their creative visions to life.

To understand why bobbins are necessary and how do bobbins work. let’s explore the steps involved in the sewing process and how bobbins play a crucial role in each stage:

How Bobbins Play A Crucial Role

1. Thread Storage And Organization:

Bobbins are essential for keeping thread neatly wound and organized. Step one involves preparing the bobbin by winding the thread tightly around it. This ensures that the thread remains untangled and easily accessible during sewing.

Bobbin Insertion into the Sewing Machine. Once the bobbin is prepared, the next step is to insert it into the sewing machine. The sewing machine typically has a designated bobbin case or compartment where the bobbin is placed. Proper insertion ensures that the bobbin sits securely in its position, ready for stitching.

2. Upper Thread Preparation:

Before stitching can begin, the upper thread needs to be prepared. This involves selecting the appropriate spool of thread and threading it through the machine’s threading path, including the needle.

3. Lower Thread Integration:

Now comes the pivotal step where the bobbin and upper thread are brought together. The bobbin, with its wound thread, is placed beneath the sewing machine’s needle. The machine’s mechanisms are designed to interlock the upper and lower threads during the stitching process.

4. Stitch Formation:

As the needle moves up and down, it passes through the fabric, interlocking the upper and lower threads. The synchronized action of the bobbin and upper thread creates stitches, forming the desired pattern or seam.

The bobbin thread is pulled up from the bottom of the fabric, while the upper thread is drawn down from the spool, resulting in a secure and balanced stitch.

5. Tension Adjustment:

Bobbins also play a vital role in controlling the tension of the thread during stitching. The sewing machine provides mechanisms to adjust the tension, which affects the tightness or looseness of the stitches.

By correctly setting the tension and considering the bobbin’s position, users can achieve consistent stitch quality and prevent issues like loose or puckered stitches.

6. Continuous Bobbin Monitoring:

Throughout the sewing process, it’s crucial to monitor the bobbin’s thread supply. When the bobbin thread runs low, it needs to be refilled or replaced with a new bobbin. Regularly checking the bobbin ensures uninterrupted stitching and prevents thread shortages or interruptions in the sewing project.

Remember:

These steps highlight the importance of how do bobbins work and their need in the sewing process. From thread storage and organization to integrating the lower thread, creating stitches, and adjusting tension, bobbins are indispensable tools for achieving smooth and precise sewing results.

How Do Fishing Bobbins Work?

Fishing bobbins are essential accessories that play a crucial role in the world of angling. Designed to detect fish bites and maintain line tension, these compact devices are indispensable tools for fishermen.

By understanding how do bobbins work in fishing bobbins, anglers can improve their chances of success on the water. These small but powerful tools respond to the tension generated when a fish takes the bait, providing a visual indicator to the angler.

Additionally, fishing bobbins help keep the fishing line taut during the fight with a fish, increasing the chances of a successful hook-set and reducing the risk of the fish shaking off.

To understand how fishing bobbins work, let’s break down the process into steps:

1. Setup:

Attach the fishing bobbin to a fishing rod’s rod pod or bank stick. The bobbin should hang just above the water surface, close to the fishing line.

2. Bait Presentation:

Cast your baited hook into the water and position your fishing rod securely in a rod holder.

3. Tension Transmission:

When a fish bites the bait and tugs on the fishing line, the tension is transmitted through the line to the fishing bobbin.

4. Bobbin Movement:

The fishing bobbin responds to the tension by moving upward, away from its resting position.

5. Visual Indicator:

The movement of the fishing bobbin serves as a visual indicator for the angler, even when they are not actively holding the fishing rod. The upward movement signals that a fish has taken the bait.

6. Line Tension Maintenance:

As the fish continues to pull on the line and tries to swim away, the fishing bobbin remains suspended in the air, exerting a gentle downward pressure on the line. This helps maintain tension, keeping the line taut during the fight.

7. Hook-Set and Landing:

The angler, alerted by the bobbin movement, can react accordingly, striking the fish to set the hook and initiating the process of reeling in the catch. The maintained line tension facilitated by the fishing bobbin reduces the risk of the fish shaking off the hook during the fight.

By following these steps, anglers can effectively utilize fishing bobbins as indicators for fish bites and tools for maintaining line tension. This enhances their ability to detect bites and increases their chances of successfully landing their target fish.

Do You Need A Fishing Bobbin With A Bite Alarm

The need for a fishing bobbin with a bite alarm depends on personal preference and fishing style. While fishing bobbins and bite alarms serve similar purposes of indicating fish activity, they have distinct functionalities. Fishing bobbins provide a visual indicator by moving upward when there is tension on the fishing line, indicating a fish bite.

Anglers who prefer actively watching the bobbin for movement may find it sufficient without the need for a bite alarm. They can visually detect bites and react accordingly. On the other hand, bite alarms are electronic devices that emit an audible or visual signal when there is fish activity.

These alarms typically consist of a receiver and a sensor that attaches to the fishing line. When a fish bites, the sensor detects the movement or tension and triggers the alarm, alerting the angler.

How do bobbins work using a bite alarm can be beneficial in situations where an angler wants to be alerted immediately, especially if they are fishing multiple rods or need to be engaged in other activities. The alarm allows them to respond promptly without constantly monitoring the fishing bobbins.

Conclusion:

Bobbins are essential tools in various industries, including sewing and textiles. These small cylindrical devices play a crucial role in storing, organizing, and dispensing thread. Neatly winding thread around the bobbin, prevents tangles and ensures easy access during the sewing process.

Additionally, how do bobbins work, well bobbins are integrated into sewing machines, where they work in tandem with the upper thread to create interlocked stitches. Their adjustable tension control allows for customized stitch quality.

From maintaining thread organization to enhancing the functionality of sewing machines, bobbins are indispensable components that contribute to efficient and high-quality stitching outcomes. I hope now you’re fully aware of how do bobbins work.

FAQs:

Q 1: How Does A Bobbin Store And Organize Threads?

A: A bobbin typically has a cylindrical shape with a central hole. The thread is wound tightly around the bobbin, creating a compact package. This winding process keeps the thread organized and prevents tangling during sewing.

Q 2: How Are Bobbins Used In Sewing Machines?

A: Sewing machines have a designated bobbin case or compartment. The bobbin is inserted into this case, and the machine’s mechanisms draw the thread from the bobbin to interlock with the upper thread. The synchronized interaction of the bobbin and upper thread creates stitches.

Q 3: What Is The Purpose Of Tension Adjustment On Bobbins?

A: Tension adjustment on bobbins helps control the tightness or looseness of stitches. By adjusting the tension, sewers can achieve balanced and even stitches. The tension setting varies depending on the fabric, thread thickness, and desired stitch quality.

Q 4: Can Bobbins Accommodate Different Types Of Threads?

A: Yes, bobbins can accommodate various types of threads, such as cotton, polyester, or specialty threads. It’s important to select a bobbin size that matches the sewing machine and ensure the thread is wound tightly and evenly for optimal performance.

Q 5: Do Bobbins Have A Role In Embroidery Or Decorative Stitching?

A: Absolutely. Bobbins are crucial for embroidery and decorative stitching. They contribute to the overall stitch quality and tension control, ensuring that intricate designs and patterns are stitched smoothly and accurately.

Q 6: Are Bobbins Only Used In Sewing?

A: While bobbins are primarily associated with sewing, they find utility in other industries as well. Bobbins are used in textile manufacturing processes like weaving and knitting, where they help store and dispense yarn or thread. They are also used in the production of electrical coils and transformers, providing a foundation for winding wire.

Q 7: How Often Should Bobbins Be Replaced Or Refilled?

A: The frequency of bobbin replacement or refilling depends on the project’s size and complexity. It is good practice to regularly monitor the bobbin’s thread supply and refill or replace it as needed to avoid interruptions in the sewing process. It’s recommended to have spare bobbins on hand to ensure uninterrupted sewing sessions.