Bottom-weight fabric refers to a category of textiles that are specifically designed for use in the creation of sturdy, durable, and heavyweight garments. What is bottom weight fabric is a interesting topic as the name suggests, these fabrics are typically used for the bottom half of clothing items, such as pants, skirts, and outerwear, where strength, structure, and resistance to wear and tear are crucial.

The primary characteristic of bottom-weight fabric is its substantial weight and density, which provides the necessary stability and support for garments that undergo frequent use and stress. Unlike lighter fabrics used for tops or blouses, bottom-weight fabrics are constructed to withstand the rigors of everyday wear, ensuring longevity and durability.

These fabrics are often made from natural fibers like cotton, wool, or blends of these fibers, as well as synthetic materials such as polyester or nylon. The choice of fiber depends on the desired qualities of the final garment, with each fiber offering its own unique benefits and characteristics. In this article, We will discuss detailed steps of What is bottom weight fabric.

Bottom-weight fabrics can range in texture and appearance, offering a variety of options to suit different design aesthetics and functional requirements. Some examples include denim, twill, corduroy, canvas, and gabardine. Knowing What is bottom weight fabric is very helpful because these fabrics are known for their resistance to wrinkling, abrasion, and stretching, making them ideal for creating well-structured bottoms that maintain their shape and withstand frequent use.

Uses Of Bottom Weight Fabrics

Whether you’re a fashion enthusiast or a sewing enthusiast, understanding the features of bottom-weight fabrics can help you make informed choices when selecting materials for durable and stylish clothing items. In this article, we will explore What is bottom weight fabric uses, providing insights into the different types available and their suitability for various garment applications.

Bottom-weight fabrics are heavyweight textiles specifically designed for creating durable, sturdy garments for the lower half of the body.

Here Are 30 Long What Is Bottom Weight Fabric Uses.

1. Pants And Trousers:

Bottom weight fabrics are commonly used for creating pants and trousers, providing structure, support, and longevity for everyday wear.

2. Jackets And Coats:

These fabrics are suitable for crafting outerwear pieces like jackets, coats, and parkas, providing durability and protection against harsh weather conditions.

3. Shorts:

Bottom weight fabrics offer comfort and support for shorts, ensuring they maintain their shape and durability during active wear.

4. Jumpsuits And Overalls:

These one-piece garments benefit from the durability and endurance of bottom-weight fabrics.

5. Work Wear:

Bottom weight fabrics are commonly used in workwear garments, such as uniforms or coveralls, due to their durability and resistance to wear and tear.

6. Aprons And Protective Clothing:

The heavyweight nature of bottom weight fabrics makes them suitable for creating aprons and protective clothing, offering durability and shielding against spills and stains.

7. Bags And Totes:

Bottom weight fabrics can be utilized for crafting sturdy bags and totes that can withstand heavy loads and regular use.

8. Upholstery:

These fabrics are suitable for creating durable upholstery for furniture, ensuring longevity and resistance to wear.

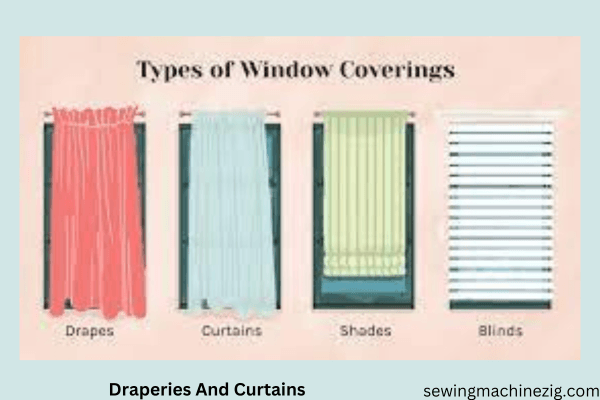

9. Draperies And Curtains:

Bottom weight fabrics can be used for creating heavy draperies and curtains that offer privacy and insulation.

10. Cushion Covers:

These fabrics are ideal for crafting cushion covers that maintain their shape and structure.

11. Tablecloths And Placemats:

Bottom weight fabrics can be used for creating sturdy tablecloths and placemats that can withstand spills and frequent use.

12. Pet Accessories:

Bottom weight fabrics are suitable for crafting durable pet beds, covers, and accessories.

13. Crafts And DIY Projects:

These fabrics are often employed in crafting projects such as fabric baskets, organizers, or sturdy DIY accessories.

14. Costumes And Cosplay:

Bottom weight fabrics provide durability and structure for costumes and cosplay outfits that require sturdiness and longevity.

15. School Uniforms:

Bottom weight fabrics are commonly used for creating school uniforms that can withstand daily wear and frequent washing.

16. Sports And Active Wear:

These fabrics offer support, durability, and comfort for sports and active wear garments like leggings, athletic pants, and shorts.

17. Maternity Wear:

Bottom weight fabrics can be utilized in creating comfortable and supportive maternity pants and skirts.

18. Dancewear:

These fabrics are suitable for creating dance costumes and practice wear that require durability and flexibility.

19. Historical And Period Costumes:

Bottom weight fabrics provide the structure and authenticity required for historical and period costumes.

20. Chef’s Aprons:

Bottom weight fabrics are perfect for creating durable and stain-resistant aprons for chefs and kitchen staff.

21. Motorcycle Gear:

These fabrics are commonly used in creating motorcycle pants and jackets for protection against abrasion and impact.

22. Gardening Attire:

Bottom weight fabrics offer durability and resistance to soil and stains, making them suitable for gardening pants and overalls.

23. Industrial Work wear:

Bottom weight fabrics are often used in the construction, manufacturing, and heavy-duty industries for protective clothing.

24. School Backpacks:

These fabrics provide strength and durability for backpacks, ensuring they can withstand heavy loads and frequent use.

25. Luggage And Suitcases:

Bottom weight fabrics are used in creating sturdy luggage and suitcases that can withstand travel and handling.

26. Outdoor Gear:

These fabrics are suitable for outdoor gear such as hiking pants, camping jackets, and fishing vests, providing durability and protection.

27. Uniforms For Security Personnel:

Bottom weight fabrics offer a professional and durable choice for security uniforms that need to withstand long hours and physical activity.

28. Equestrian Apparel:

These fabrics are utilized in creating riding breeches and jodhpurs for equestrian activities, providing comfort, durability, and flexibility.

29. Construction And Trades Clothing:

Bottom-weight fabrics are commonly used for workwear in construction, carpentry, plumbing, and other trades, providing durability and protection.

30. Skirts:

Bottom-weight fabrics are ideal for skirts that require stability and shape retention, such as A-line, pencil, or pleated skirts.

Advantages of Bottom Weight Fabrics

1. Durability:

Bottom-weight fabrics are known for their durability, ensuring garments made from them can withstand frequent use and last for a long time.

2. Structure And Support:

These fabrics offer excellent structure, giving garments a well-defined shape and a polished appearance.

3. Wrinkle Resistance:

Bottom-weight fabrics are typically less prone to wrinkling, reducing the need for frequent ironing or pressing.

4. Versatility:

Bottom-weight fabrics come in various types, textures, and finishes, providing versatility in design options to suit different fashion aesthetics and preferences.

5. Comfort:

Despite their heavyweight nature, many bottom-weight fabrics are designed to provide comfort and ease of movement, with options like a stretch or natural fiber blends offering breathability.

6. Shape Retention:

Bottom-weight fabrics hold their form well, ensuring garments maintain their intended silhouette over time.

7. Resistance To Wear And Tear:

These fabrics are constructed to withstand the rigors of regular use, making them resistant to abrasion and tearing.

8. Stain Resistance:

Many bottom-weight fabrics have stain-resistant properties, making them suitable for garments exposed to spills or frequent handling.

9. Insulation:

Some bottom-weight fabrics, like wool blends, offer insulation and warmth, making them ideal for cooler-weather garments.

10. Professional Appearance:

Garments made from bottom-weight fabrics often have a more polished and structured look, suitable for professional or formal settings.

11. Fade Resistance:

Bottom weights fabric is often treated to be fade-resistant, ensuring colors remain vibrant even with repeated washes and exposure to sunlight.

12. Easy Care:

Many bottom-weight fabrics are machine washable and require minimal ironing, making them convenient for everyday wear.

13. Longevity:

Due to their durability and resistance to wear, garments made from bottom weight fabrics tend to have a longer lifespan compared to lighter-weight materials.

14. Shape Recovery:

Bottom weight fabrics often have good shape recovery properties, meaning they bounce back to their original shape after stretching or bending.

15. Versatile Color Options:

These fabrics come in a wide range of colors and prints, allowing for versatile design choices and creative expression.

16. Breathability:

Natural fiber bottom-weight fabrics like cotton or linen blends offer breathability, keeping the wearer comfortable in various climates.

17. UV Protection:

Some bottom-weight fabrics offer UV protection, shielding the wearer from harmful sun rays.

18. Easy to Sew:

What is bottom weight fabric. fabrics are generally easy to sew due to their stability and less tendency to shift or stretch during the sewing process.

19. Eco-Friendly Options:

Sustainable bottom-weight fabrics made from organic or recycled fibers are available, providing environmentally friendly choices for conscious consumers.

20. Classic Style:

Bottom-weight fabrics are often associated with timeless, classic styles, making them a reliable choice for long-lasting wardrobe staples.

How To Make Bottom Weight Fabric And Sew

Bottom-weight fabric is a specialized textile primarily used for creating sturdy and durable bottoms, such as pants, skirts, and shorts. It is important to understand What is bottom weight fabric so the process of making and sewing with bottom-weight fabric to achieve the best results. Here is a detailed explanation of the materials needed, along with eight steps to guide you through the process:

Materials:

- Cotton Duck: A heavy and durable fabric commonly used for workwear and heavy-duty bottoms.

- Stretch Sateen: A smooth and stretchy fabric with a slight sheen, perfect for fitted pants or skirts.

- Corduroy: A ribbed fabric with vertical or horizontal ridges, providing warmth and texture to bottoms.

- Wool Gabardine: A fine wool fabric with a twill weave, ideal for tailored trousers or skirts.

Step-By-Step Guide:

Step 1: Fabric Selection:

Choose the appropriate bottom weight fabric based on the desired characteristics, such as weight, texture, and stretch. For example, select a medium-weight stretch sateen for a pair of comfortable yet elegant pants.

Step 2: Pattern Preparation:

Select a pattern that matches your desired style and size. Make sure it is suitable for the chosen fabric. Cut out the pattern pieces, leaving enough space for seam allowances. Leave approximately 1.5 inches on both the left and right sides for adjustments and fitting.

Step 3: Fabric Preparation:

Place the chosen fabric on a flat surface, ensuring it is free from wrinkles and creases. Position the pattern pieces on the fabric according to the grainline and desired orientation. Secure the pattern pieces with pins or pattern weights.

Step 4: Cutting:

Using sharp fabric scissors or a rotary cutter, carefully cut along the designated lines of the pattern pieces. Leave a consistent seam allowance of about 0.5 inches on both the left and right sides of each piece.

Step 5: Marking:

Transfer important pattern markings, such as notches and darts, onto the fabric using tailor’s chalk or fabric markers. These markings serve as guides during the sewing process. Make sure to place them accurately and distinctly on the fabric.

Step 6: Construction And Sewing:

Follow the pattern instructions to assemble the fabric pieces. Utilize appropriate sewing techniques, such as straight stitches or zigzag stitches, depending on the fabric type and desired finish. For example, sew the side seams of the pants, leaving a 0.5-inch seam allowance on both sides.

Step 7: Fitting And Adjustments:

After sewing, try on the garment to assess the fit. Make any necessary adjustments, such as taking in or letting out the seams, to achieve the desired fit and comfort. Consider the initial seam allowance when making adjustments.

Step 8: Finishing Touches:

Complete the garment by finishing the edges and hems. This can be done through techniques like serging, folding, and stitching, or adding facings. For example, finish the hem of a skirt by folding the fabric under by 0.5 inches on both the left and right sides and stitch in place.

What is bottom weight fabric . The answer is By following these eight steps and ensuring accurate measurements, you can successfully create bottoms using bottom-weight fabric. Remember to allow for seam allowances and make fitting adjustments as needed to achieve a well-fitting and professionally sewn garment.

What Is Bottom Weight Denim

Bottom-weight denim is a heavyweight fabric known for its durability and versatility. It is a variant of traditional denim but with a denser and heavier construction. This type of denim is specifically designed for creating bottoms, such as jeans, skirts, and shorts that require structure and durability. It’s related to What is bottom weight fabric.

Bottom-weight denim offers the classic denim aesthetic along with enhanced durability and a substantial feel. It is characterized by its weight, typically ranging from 10 to 16 ounces per square yard, making it thicker and sturdier than lighter-weight denim. Hope now you understand What is bottom weight fabric denim with its ability to withstand everyday wear and tear, bottom-weight denim is a popular choice for creating long-lasting and stylish garments.

Here is a list of materials on what is bottom weight fabric denim and commonly used in bottom heavyweight denim production, along with their brief explanations:

1. Cotton:

Natural fiber is known for its breathability, softness, and durability, commonly used as the primary material in bottom heavyweight denim.

2. Polyester:

A synthetic fiber that offers strength, wrinkle resistance, and colorfastness, often blended with cotton to enhance the durability of heavyweight denim.

3. Spandex:

A stretchy synthetic fiber that provides flexibility and comfort, commonly added to heavyweight denim for improved mobility and fit.

4. Rayon:

A semi-synthetic fiber made from cellulose, known for its softness, drape, and breathability, sometimes used in blends for heavyweight denim.

5. Modal:

A type of rayon known for its luxurious softness, moisture-wicking properties, and resistance to shrinking and fading, used in premium heavyweight denim.

6. Lyocell:

A sustainable and eco-friendly fiber made from wood pulp, offering excellent moisture absorption and breathability, used in high-quality heavyweight denim.

7. Tencel:

A branded lyocell fiber known for its strength, softness, and environmental sustainability, used to enhance the quality of heavyweight denim.

8. Viscose:

A semi-synthetic fiber with a silky texture and good drape, often used in blends with cotton for added softness and comfort in heavyweight denim.

9. Acrylic:

A synthetic fiber that provides warmth, softness, and lightweight properties, sometimes used in blends to enhance the insulation of heavyweight denim.

10. Nylon:

A synthetic fiber is known for its strength and abrasion resistance, occasionally used in heavyweight denim for added durability and toughness.

11. Linen:

A natural fiber made from flax plants, offering breathability, coolness, and natural texture, used in heavyweight denim for a rugged and textured appearance.

12. Hemp:

A sustainable natural fiber known for its strength, durability, and environmental benefits, sometimes incorporated into heavyweight denim for added toughness.

13. Wool:

A natural fiber sourced from animal fleece, providing insulation, warmth, and moisture-wicking properties, used in heavyweight denim for colder climates.

14. Elastane:

A synthetic fiber also known as spandex or Lycra, is used in small amounts in heavyweight denim to add stretch and shape retention.

15. Polypropylene:

A lightweight and moisture-wicking synthetic fiber often used in performance denim for its quick-drying properties and enhanced comfort.

16. Polyamide:

Synthetic fiber is known for its strength, durability, and resistance to abrasion, occasionally used in heavyweight denim for increased toughness.

17. Cordura:

A highly durable and tear-resistant fabric made from nylon sometimes used as a reinforcement material in heavyweight denim for added strength.

18. Polyurethane:

A synthetic material used in fabric coatings or as an additive to provide stretch, water resistance, and durability to heavyweight denim.

19. Acetate:

A semi-synthetic fiber with a silk-like appearance and good draping qualities, used in blends to add softness and luster to heavyweight denim.

20. Cupro:

A regenerated cellulose fiber made from cotton linter, offering excellent moisture absorption and breathability, occasionally used in heavyweight denim for added comfort.

These materials, either individually or in combination, contribute to the durability, comfort, and overall quality of bottom heavyweight denim, ensuring that the garments made from it are robust and long-lasting. I hope now you’re fully aware of What is bottom weight fabric.

Conclusion:

Bottom-weight fabric is a type of fabric that is specifically designed for use in making bottoms such as pants, skirts, and shorts. It is characterized by its heavier weight, which provides structure, durability, and coverage for these garments. What is bottom weight fabric; well bottom weight fabrics are often made from materials like cotton, polyester, and spandex, which offer a balance of comfort, strength, and flexibility.

They are versatile and can be used to create a wide range of bottom styles, from casual to formal. Whether you’re looking for jeans, tailored trousers, or a flowing skirt, bottom-weight fabrics are an essential choice for ensuring the longevity and functionality of your bottom garments.

FAQs:

Q 1: What Is Bottom Weight Fabric?

A: What is bottom weight fabric, Fabric refers to a specialized type of textile that is specifically designed for creating sturdy and durable bottoms, such as pants, skirts, and shorts. It is typically heavier in weight compared to fabrics used for tops or dresses.

Q 2: What Are The Characteristics Of Bottom Weight Fabric?

A: Bottom-weight fabrics are known for their durability, stability, and resistance to wear and tear. They often have a heavier or denser weave, providing structure and support to the garments. They can vary in composition, including materials like cotton twill, denim, wool blends, and corduroy.

Q 3: What Are The Advantages Of Using Bottom Weight Fabric?

A: Using What is bottom weight fabric. It offers several advantages. They provide better shape retention, longevity, and durability, making them suitable for everyday wear. The heavier weight also helps to create a flattering silhouette by holding its shape and providing a structured appearance.

Q 4: Can Bottom Weight Fabric Be Used For Other Projects Besides Bottoms?

A: While bottom-weight fabric is primarily used for bottoms, it can also be used for other projects that require a sturdy and durable fabric, such as tote bags, upholstery, and home decor items. Its versatility makes it a popular choice for various sewing projects.

Q 5: How Should I Care For Garments Made With Bottom Weight Fabric?

A: Garments made with bottom-weight fabric typically require special care. Always check the fabric care instructions, but in general, they may need to be washed on a gentle cycle, preferably in cold water, and dried on a low or medium heat setting. Avoid excessive agitation or high heat, as it can cause shrinkage or damage to the fabric.

Q 6: Can I Sew Bottom Weight Fabric With A Regular Sewing Machine?

A: Yes, the bottom-weight fabric can be sewn using a regular sewing machine. However, due to the thickness and density of the fabric, it is advisable to use appropriate sewing techniques, such as using a heavier needle, adjusting the tension, and utilizing reinforced stitches for added strength.

Q 7: Can I Mix Different Bottom Weight Fabrics In One Garment?

A: Yes, you can mix different bottom-weight fabrics in one garment to create unique and contrasting designs. For example, you might use a denim fabric for the main body of a skirt and a cotton twill fabric for the waistband or pocket lining. Just ensure that the fabrics you choose work well together in terms of weight, stretch, and drape.