In the symphony of sewing, a simple yet crucial note is struck when considering needle changes. The question lingers: “How to change a sewing machine needle?” This guide intricately dissects the process, offering a harmonious blend of clarity and expertise.

As we navigate the delicate dance between needle and fabric, you’ll uncover the art of seamless needle replacement. Join us on this transformative journey, where the seemingly mundane act of changing a sewing machine needle becomes a pivotal skill, enhancing your stitching prowess and ensuring every project is a masterpiece in the making.

How To Change A Sewing Machine Needle Detailed Answer

A Stitch in Time: How To Change a Sewing Machine Needle – A Step-by-Step Guide to Needle Replacement

Sewing enthusiasts understand the importance of a well-maintained sewing machine, and one often overlooked yet crucial element is the sewing machine needle. Whether you’re a seasoned sewist or a novice, knowing How to change a sewing machine needle is a fundamental skill that can significantly impact the quality of your stitches and the overall performance of your machine.

In this comprehensive guide, we’ll take you through each step of the process, providing detailed instructions on “How to change a sewing machine needle.”

Step 1: Gather Your Materials

Before embarking on the needle-changing journey, ensure you have all the necessary materials at hand. You’ll need a new sewing machine needle (appropriate for your fabric and project), a small screwdriver (often included in your sewing machine accessories), and, if needed, a pair of tweezers.

Step 2: Turn Off Your Sewing Machine

Safety first! Before making any adjustments to your sewing machine, turn it off and unplug it from the power source. This precaution ensures that there’s no risk of injury while you’re working on the needle replacement.

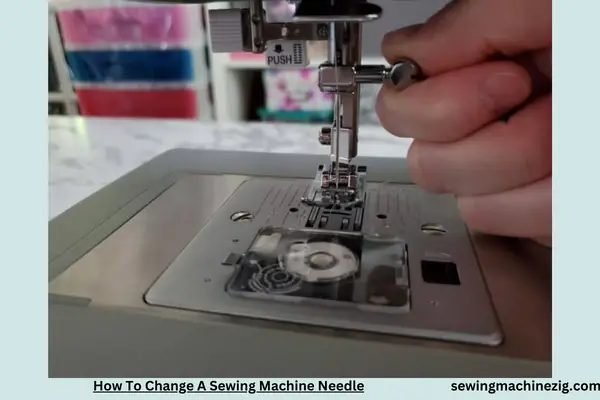

Step 3: Raise the Needle to Its Highest Position

Maneuver the handwheel on the side of your sewing machine to raise the needle to its highest position. This step is crucial as it provides you with better access to the needle and ensures that the needle clamp is fully open.

Step 4: Remove the Presser Foot

To gain clear access to the needle, remove the presser foot. This step is especially helpful when dealing with a low shank sewing machine, as it allows more space for the needle replacement process.

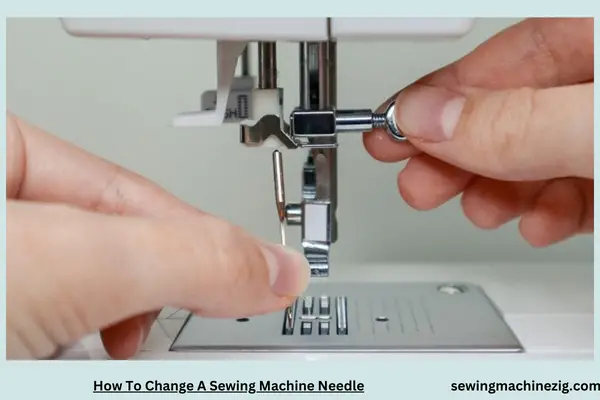

Step 5: Loosen the Needle Clamp Screw

Using the small screwdriver, loosen the needle clamp screw. The location of this screw may vary depending on your sewing machine model, but it’s typically found on the side or back of the needle clamp. Turn the screw counterclockwise to loosen it without fully removing it.

Step 6: Remove the Old Needle

Once the needle clamp screw is sufficiently loosened, carefully slide the old needle out of the needle clamp. If the needle is bent or damaged, use tweezers to grasp it securely and avoid any accidental pricks. Dispose of the old needle properly.

Step 7: Examine the Needle Type and Size

Before inserting the new needle, take a moment to check the type and size of the needle. The appropriate needle for your project depends on the fabric you’re using. Refer to your sewing machine manual for guidance on choosing the right needle for specific fabrics and techniques.

Step 8: Insert the New Needle

Hold the new needle with the flat side facing the back of the machine. Carefully insert the needle into the needle clamp as far up as it will go. Ensure that the needle is positioned correctly, with the flat side against the back and the rounded side facing the front.

Step 9: Tighten the Needle Clamp Screw

Once the new needle is securely in place, use the screwdriver to tighten the needle clamp screw. Ensure that it is snug but not overtightened. A moderate level of tightness is sufficient to keep the needle in place during sewing.

Step 10: Check the Needle Alignment

After tightening the needle clamp screw, double-check the alignment of the needle. It should be straight and not tilted to either side. A misaligned needle can result in stitching issues, so take a moment to make sure it’s perfectly straight.

Step 11: Reattach the Presser Foot

If you removed the presser foot earlier, now is the time to reattach it. Make sure it is securely fastened, and if your sewing machine has a presser foot lever, lower it to engage the presser foot with the fabric.

Step 12: Perform a Test Stitch

Before diving into your actual project, perform a test stitch on a scrap piece of fabric. This allows you to ensure that the new needle is functioning correctly and that there are no issues with the stitching. Pay attention to the stitch quality and listen for any unusual noises.

Step 13: Adjust Tension and Stitch Length if Necessary

If the test stitch reveals any tension issues or irregularities in stitch length, you may need to make adjustments. Consult your sewing machine manual for guidance on adjusting tension and stitch length to achieve the desired results.

Step 14: Dispose of the Old Needle Safely

Dispose of the old needle in a safe and responsible manner. Many localities have guidelines for the proper disposal of sewing machine needles. Some recommend placing the old needle in a container or using a needle disposal kit.

Step 15: Make a Note of the Needle Change

For your own reference, and especially if you work on multiple projects, consider making a note of the date and type/size of the needle change. This information can be helpful in maintaining a regular needle replacement schedule and ensuring optimal stitching results.

Step 16: Routine Needle Maintenance

In addition to changing the needle when necessary, incorporating routine needle maintenance into your sewing habits is essential. Regularly check the needle for any signs of damage or dullness. If you notice skipped stitches, thread breakage, or other issues, it may be an indicator that the needle needs replacement.

Step 17: Experiment with Different Needles

As you advance in your sewing skills, don’t hesitate to experiment with different types of needles for various fabrics and techniques. Needles come in a variety of types, including ballpoint, universal, quilting, and more. Trying different needles allows you to fine-tune your stitching for specific projects.

Sewing Success with Proper Needle Care

Changing a sewing machine needle is a simple yet crucial task that can significantly impact the quality of your stitches. By following this comprehensive step-by-step guide, you’ve equipped yourself with the knowledge and skills to change a sewing machine needle seamlessly. Incorporate proper needle care into your sewing routine, and you’ll enjoy consistent stitching success in all your creative endeavors. Happy stitching!

How Often Do You Change Sewing Machine Needles

Preserving Precision: How Often Do You Change Sewing Machine Needles? A Comprehensive Guide to Needle Replacement Frequencies

Embarking on a sewing project is an exciting endeavor, but the success of your creations hinges on the often-overlooked component – the sewing machine needle. Many sewing enthusiasts may find themselves wondering, “How often do you change sewing machine needles?”

In this detailed guide, we will unravel the intricacies of needle longevity, providing a step-by-step exploration and answering the critical question of when and how to change sewing machine needles for optimal stitching performance.

Step 1: Understanding the Importance of Needle Maintenance

Before delving into the frequency of needle changes, it’s crucial to recognize the vital role needles play in the sewing process. The needle is responsible for piercing through fabrics, creating stitches, and impacting the overall quality of your finished projects. Regular needle maintenance is key to ensuring precise stitches and preventing issues like thread breakage, skipped stitches, and fabric damage.

Step 2: Assessing Factors That Affect Needle Lifespan

Several factors influence how quickly a sewing machine needle wears out. Consider the following factors when evaluating the longevity of your needles:

- Fabric Type: Sewing through heavy fabrics, denim, or materials with a high fiber content can accelerate needle wear.

- Project Complexity: Intricate projects with frequent starts and stops, as well as numerous direction changes, can contribute to needle wear.

- Thread Quality: Poor-quality or linty threads can increase friction and impact the lifespan of your needle.

- Machine Speed: Sewing at high speeds generates more heat, potentially causing needles to wear out faster.

Step 3: Regular Needle Inspection

To determine if it’s time to change your sewing machine needle, regularly inspect it for signs of wear. Look for the following indicators:

- Bent or Blunt Tip: A bent or blunt needle tip can result in uneven stitches and fabric damage.

- Visible Damage: Any visible nicks, scratches, or bends on the needle warrant immediate replacement.

- Rust or Corrosion: Rusty needles can leave stains on fabrics and compromise stitching quality.

Step 4: Frequency Recommendations by Sewing Experts

While there is no one-size-fits-all answer to how often you should change your sewing machine needle, many sewing experts provide general recommendations:

- Every 8-10 Hours of Sewing: For avid sewists engaging in prolonged sewing sessions, changing the needle every 8-10 hours is a common suggestion.

- At the Start of Each Project: Some recommend changing the needle at the beginning of each new project to ensure optimal stitching quality.

- After Sewing Through Bulky Fabrics: If you’ve been sewing through heavy fabrics like denim or multiple layers, consider changing the needle to maintain precision.

- When Switching Thread Types: Changing from one thread type to another may necessitate a needle change to avoid thread breakage and tension issues.

Step 5: Signs It’s Time to Change the Needle

Certain telltale signs indicate that it’s time to change your sewing machine needle:

- Audible Clicking or Popping Sounds: Unusual sounds during sewing may indicate a damaged or dull needle.

- Fabric Snags or Pulls: If your fabric is snagging or pulling, it’s a clear sign that the needle is not piercing smoothly.

- Uneven Stitches: Inconsistent stitch quality, such as skipped stitches or irregular tension, can result from a worn-out needle.

Step 6: Choosing the Right Needle for Your Project

Understanding that needle choice is not only about frequency but also about selecting the right needle for your project is crucial. Needles come in various types, including universal, ballpoint, quilting, and more. Refer to your sewing machine manual and consider the fabric and project requirements when choosing a needle type.

Step 7: Gather Your Materials for Needle Replacement

When you determine that it’s time for a needle change, gather the necessary materials: a new sewing machine needle (appropriate for your fabric and project), a small screwdriver (if needed for your machine), and, if necessary, a pair of tweezers.

Step 8: Follow Manufacturer Guidelines

Check your sewing machine’s manual for specific guidelines on changing needles. Different machines may have slight variations in the process, so consulting the manufacturer’s recommendations ensures a seamless needle replacement.

Step 9: Turn Off Your Sewing Machine

As a safety precaution, turn off your sewing machine and unplug it from the power source before attempting to change the needle. This prevents any accidental injuries during the process.

Step 10: Raise the Needle to Its Highest Position

Maneuver the handwheel on the side of your sewing machine to raise the needle to its highest position. This step provides better access to the needle and ensures the needle clamp is fully open.

Step 11: Remove the Presser Foot

To enhance access to the needle, remove the presser foot. This step is particularly helpful when dealing with low shank sewing machines.

Step 12: Loosen the Needle Clamp Screw

Using the small screwdriver, loosen the needle clamp screw. The location of this screw may vary depending on your sewing machine model, but it’s typically found on the side or back of the needle clamp. Turn the screw counterclockwise to loosen it without fully removing it.

Step 13: Remove the Old Needle

Once the needle clamp screw is sufficiently loosened, carefully slide the old needle out of the needle clamp. If the needle is bent or damaged, use tweezers to grasp it securely and avoid any accidental pricks. Dispose of the old needle properly.

Step 14: Insert the New Needle

Hold the new needle with the flat side facing the back of the machine. Carefully insert the needle into the needle clamp as far up as it will go. Ensure that the needle is positioned correctly, with the flat side against the back and the rounded side facing the front.

Step 15: Tighten the Needle Clamp Screw

Once the new needle is securely in place, use the screwdriver to tighten the needle clamp screw. Ensure that it is snug but not overtightened. A moderate level of tightness is sufficient to keep the needle in place during sewing.

Step 16: Check the Needle Alignment

After tightening the needle clamp screw, double-check the alignment of the needle. It should be straight and not tilted to either side. A misaligned needle can result in stitching issues, so take a moment to make sure it’s perfectly straight.

Step 17: Reattach the Presser Foot

If you removed the presser foot earlier, now is the time to reattach it. Make sure it is securely fastened, and if your sewing machine has a presser foot lever, lower it to engage the presser foot with the fabric.

Step 18: Perform a Test Stitch

Before diving into your actual project, perform a test stitch on a scrap piece of fabric. This allows you to ensure that the new needle is functioning correctly and that there are no issues with the stitching. Pay attention to the stitch quality and listen for any unusual noises.

Step 19: Adjust Tension and Stitch Length if Necessary

If the test stitch reveals any tension issues or irregularities in stitch length, you may need to make adjustments. Consult your sewing machine manual for guidance on adjusting tension and stitch length to achieve the desired results.

Step 20: Dispose of the Old Needle Safely

Dispose of the old needle in a safe and responsible manner. Many localities have guidelines for the proper disposal of sewing machine needles. Some recommend placing the old needle in a container or using a needle disposal kit.

Step 21: Record the Date and Needle Type

To keep track of your needle changes, consider recording the date and the type of needle you installed. This information can be valuable for maintaining a regular needle replacement schedule and troubleshooting stitching issues.

Step 22: Routine Needle Maintenance

In addition to changing the needle when necessary, incorporate routine needle maintenance into your sewing habits. Regularly check the needle for any signs of damage or dullness. If you notice skipped stitches, thread breakage, or other issues, it may be an indicator that the needle needs replacement.

Step 23: Experiment with Different Needles

As you advance in your sewing skills, don’t hesitate to experiment with different types of needles for various fabrics and techniques. Needles come in a variety of types, including ballpoint, universal, quilting, and more. Trying different needles allows you to fine-tune your stitching for specific projects.

Mastering the Art of Needle Care

In conclusion, the question of “How often do you change sewing machine needles?” is a nuanced one, with various factors influencing the frequency of needle replacement.

By following this comprehensive step-by-step guide, you’ve gained insights into not only when to change your needle but also how to do it seamlessly for optimal stitching results. Mastering the art of needle care ensures that your sewing machine remains a reliable tool, consistently delivering precise and beautiful stitches in all your creative endeavors. Happy stitching!

Conclusion

To conclude, the art of “How to change a sewing machine needle” is a simple yet pivotal skill for any sewing enthusiast. Regular needle changes ensure precise stitching and prevent damage to fabrics. Following the straightforward steps outlined in this guide empowers you to effortlessly swap needles, enhancing the overall performance of your sewing machine.

By embracing this routine maintenance, you guarantee that each stitch is a testament to the precision and care invested in your sewing projects, fostering a seamless and enjoyable sewing experience. “How to change a sewing machine needle“

FAQs for “How To Change A Sewing Machine Needle”

Q1: Why is it necessary to change the sewing machine needle regularly?

A1: Regular needle changes prevent issues like skipped stitches, and fabric damage, and ensure optimal stitching quality. It’s a crucial part of machine maintenance. “How to change a sewing machine needle“

Q2: How often should I change the needle on my sewing machine?

A2: Change the needle after every 8–10 hours of sewing, or more frequently if you notice any issues like snagging or uneven stitches. “How to change a sewing machine needle“

Q3: Can I use any needle for my sewing machine, or are there specific types?

A3: It’s essential to use the right needle type for your fabric and project. Consult your machine’s manual for the recommended needle types.

Q4: Can a dull or bent needle affect the quality of my stitches?

A4: Yes, a dull or bent needle can cause various issues, including skipped stitches, fabric puckering, and damage. Regular changes ensure optimal performance. “How to change a sewing machine needle“

Q5: Is it necessary to turn off the sewing machine before changing the needle?

A5: Yes, for safety, always turn off the machine and unplug it before changing the needle to prevent accidental starts. “How to change a sewing machine needle“

Q6: How can I determine the correct needle size for my sewing project?

A6: The needle size depends on the fabric type and weight. Check your machine’s manual for a needle size guide or consult sewing references. “How to change a sewing machine needle“