Maintaining a well-functioning sewing machine involves understanding crucial elements like tension discs. In this comprehensive guide on “How to Clean Tension Discs Sewing Machine,” we delve into the importance of this maintenance task. Over time, lint and debris can accumulate, affecting your machine’s performance.

By following our step-by-step instructions, specifically tailored for cleaning tension discs, you’ll ensure smooth thread tension, ultimately enhancing the quality of your stitches. Let’s explore the intricacies of this process to keep your sewing machine operating at its best.

How To Clean Tension Discs Sewing Machine Detailed Answer

Embarking on the task of cleaning tension discs on your sewing machine is crucial for maintaining optimal stitch quality. Here’s a detailed step-by-step guide on How to Clean Tension Discs Sewing Machine, ensuring your machine operates smoothly and produces impeccable stitches:

Step 1: Gather Supplies

Before starting, assemble the necessary supplies. You’ll need a small, soft brush (such as a dedicated sewing machine brush), compressed air or a handheld air blower, and lint-free cloths.

Step 2: Power Off and Unplug

Ensure your sewing machine is turned off and unplugged to guarantee safety during the cleaning process.

Step 3: Raise the Presser Foot

Lift the presser foot to release tension on the discs, allowing easier access for cleaning.

Step 4: Remove the Thread

Completely remove the thread from the machine, both from the needle and the bobbin.

Step 5: Locate the Tension Discs

Consult your sewing machine manual to identify the location of the tension discs. In most machines, you’ll find them near the threading path and just above the needle.

Step 6: Brush Away Visible Debris

Using the small brush, gently sweep away any visible lint, dust, or debris on and around the tension discs. Pay attention to the entire threading path.

Step 7: Use Compressed Air

With the presser foot still raised, use compressed air or a handheld air blower to blow away any remaining loose particles. This ensures a thorough cleaning of hard-to-reach areas.

Step 8: Flossing Technique

Cut a small piece of lint-free cloth or use a specialized flossing tool designed for sewing machines. Insert it between the tension discs and gently move it back and forth to dislodge any trapped debris.

Step 9: Rotate the Handwheel

Manually rotate the handwheel to expose different parts of the tension discs, repeating the brushing and flossing process until no more debris is visible.

Step 10: Inspect and Reassemble

Take a moment to inspect the tension discs for cleanliness. Once satisfied, rethread your sewing machine, following the machine’s manual for the correct threading sequence.

Step 11: Test the Tension

Sew a few test stitches on a scrap piece of fabric to ensure the tension is balanced and that there are no issues after cleaning.

Step 12: Regular Maintenance

Incorporate cleaning the tension discs into your regular sewing machine maintenance routine. Aim to clean them every few weeks, depending on how frequently you use your machine.

Key Points to Remember:

- Gentleness is Key: Be delicate when cleaning tension discs to avoid damaging them.

- Use Appropriate Tools: Stick to tools recommended in your machine’s manual to prevent damage.

- Consult Your Manual: Always refer to your sewing machine manual for specific instructions and guidelines tailored to your machine model.

By following these comprehensive steps on How to Clean Tension Discs Sewing Machine, you ensure the longevity and optimal performance of your machine. Regular maintenance contributes to consistent stitch quality, making your sewing experience more enjoyable and trouble-free.

How To Clean Your Sewing Machine

Cleaning your sewing machine is a crucial aspect of maintenance that ensures optimal performance and extends its lifespan.

Follow this detailed step-by-step guide on how to clean your sewing machine, keeping it in top-notch condition for your creative endeavors.

Step 1: Gather Your Cleaning Supplies

Assemble your cleaning supplies, including a small brush, lint-free cloth, sewing machine oil, a screwdriver, and a soft brush.

Step 2: Turn Off and Unplug

Always start by turning off your sewing machine and unplugging it from the power source to ensure safety during the cleaning process.

Step 3: Remove the Needle and Presser Foot

Remove the needle and presser foot from your sewing machine. This step allows easier access to various components that require cleaning.

Step 4: Take Out the Bobbin and Bobbin Case

Remove the bobbin and the bobbin case. Check for any lint or thread remnants in these areas, as they can affect the machine’s performance.

Step 5: Clean the Feed Dogs

Use a small brush to clean the feed dogs thoroughly. These are the teeth-like mechanisms that move the fabric through the machine. Remove any accumulated lint or debris.

Step 6: Remove the Needle Plate

Unscrew the needle plate and remove it. Clean the area beneath it using the brush, ensuring all lint and dust are cleared away.

Step 7: Brush Around the Bobbin Case Area

With the bobbin case removed, use the brush to clean around the bobbin case area. Pay special attention to any small crevices where lint may accumulate.

Step 8: Clean the Tension Discs

Slide a piece of fabric or a lint-free cloth between the tension discs to remove any built-up lint. Proper tension is crucial for even stitches.

Step 9: Oil the Machine

Apply a small amount of sewing machine oil to designated points, following your machine’s manual for guidance. This lubricates essential parts, preventing friction and ensuring smooth operation.

Step 10: Wipe Down the Exterior

Use a lint-free cloth slightly dampened with water or a mild cleaning solution to wipe down the exterior of your sewing machine. Remove any dust or residue that may have settled on the surface.

Step 11: Check the Bobbin Winder

If your machine has a bobbin winder, check and clean this area as well. Ensure that it is free from lint and operates smoothly.

Step 12: Reassemble Your Machine

Carefully reassemble all the components you removed during the cleaning process. Make sure everything is securely in place.

Step 13: Test Run

Before starting a new project, run a few test stitches on scrap fabric to ensure that your sewing machine is functioning correctly after the cleaning process.

Step 14: Regular Maintenance

Incorporate regular cleaning sessions into your sewing routine to prevent excessive lint build-up and ensure your machine operates efficiently over time.

By following these detailed steps on How to Clean Tension Discs Sewing Machine, you contribute to its longevity and maintain consistent stitching quality. Remember to clean your machine regularly, especially if you frequently work with fabrics that produce more lint.

How Do I Know If My Sewing Machine Tension Is Bad?

Recognizing and addressing sewing machine tension issues is crucial for achieving perfect stitches. Follow this comprehensive guide on how to identify if your sewing machine tension is bad and learn the steps to remedy the problem.

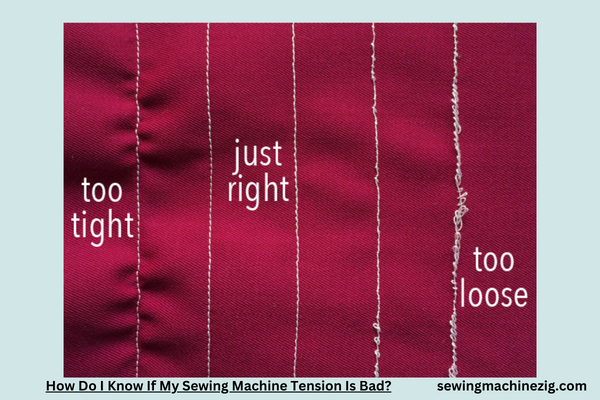

Signs of Bad Tension:

Loops or Knots on the Underside:

- If you notice loops or knots on the underside of your fabric, your tension may be too loose. This indicates that the upper thread is not adequately tight.

Puckering or Gathering:

- Puckering or gathering on the fabric surface suggests that the tension is too tight. The threads are pulling too strongly, causing the fabric to pucker.

Visible Top or Bottom Threads:

- If you can see the top thread on the bottom side of your fabric or vice versa, it indicates an imbalance in tension.

Uneven Stitch Appearance:

- Uneven stitches where the top and bottom threads don’t interlock properly suggest tension issues. Proper tension should result in a balanced, neatly formed stitch.

Breaking Threads:

- Threads that frequently break during sewing may be a sign of tension problems. Excessive tension can lead to thread breakage.

Steps to Check and Adjust Tension:

Thread the Machine Correctly:

- Ensure that you’ve correctly threaded both the upper thread and the bobbin. Improper threading can contribute to tension issues.

Use Quality Thread:

- Low-quality or old thread can lead to tension problems. Opt for high-quality thread appropriate for your fabric.

Check the Needle:

- A bent or dull needle can cause tension issues. Replace the needle regularly, especially if you’re experiencing stitching problems.

Understand Your Machine’s Tension Settings:

- Refer to your sewing machine manual to understand the recommended tension settings for different fabrics and stitches.

Perform Tension Tests:

- Sew a test strip on a scrap piece of fabric using different tension settings. Examine the results to identify the setting that produces balanced stitches.

Adjust the Upper Thread Tension:

- Most machines have a dial or digital setting for adjusting upper thread tension. Gradually adjust and test until you achieve the desired stitch quality.

Check Bobbin Tension:

- Inspect the bobbin for proper winding and placement. Some machines allow for bobbin tension adjustments.

Clean the Machine:

- Dust and lint build-up can affect tension. Regularly clean your machine, especially around the tension discs and bobbin area.

Re-Thread the Machine:

- If in doubt, re-thread both the upper thread and the bobbin, ensuring they are correctly threaded through all guides and tension discs.

Seek Professional Assistance:

- If tension issues persist despite your efforts, consider consulting a professional technician to inspect and service your sewing machine.

Regularly monitoring your sewing machine for tension issues and taking proactive measures to address them ensures smooth and precise stitching. By following these steps, you empower yourself to diagnose and rectify tension problems, enhancing the overall performance of your sewing machine.”How to Clean Tension Discs Sewing Machine“

Conclusion

In conclusion, understanding how to clean tension discs on a sewing machine is pivotal for maintaining optimal performance. Following the step-by-step guide ensures longevity and consistent stitching quality. Regular maintenance, including cleaning tension discs, safeguards against thread-related issues and promotes smooth sewing experiences.

By incorporating this routine into your sewing machine care, you contribute to its overall health and longevity, enhancing your ability to embark on diverse and intricate sewing projects with confidence and precision. Keep your machine in top condition for a seamless sewing journey. “How to Clean Tension Discs Sewing Machine“

FAQS

Q1: Why is cleaning tension discs essential for my sewing machine?

A: Regularly cleaning tension discs is crucial to ensure smooth thread flow and prevent buildup that can affect your sewing machine’s performance. This maintenance step helps maintain optimal tension for accurate stitching.

Q2: How often should I clean the tension discs of my sewing machine?

A: The frequency of cleaning depends on usage. For heavy users, cleaning every 8–10 hours of sewing is advisable. Light users can perform this maintenance every 15–20 hours. Always consult your machine’s manual for manufacturer-specific recommendations.

Q3: Can I clean tension discs without professional help?

A: Yes, you can. Start by turning off the machine and consulting your manual for guidance. Use a lint brush, compressed air, or a soft cloth to remove lint or debris. Avoid using sharp objects to prevent damage to the delicate tension discs. “How to Clean Tension Discs Sewing Machine“

Q4: What signs indicate that my sewing machine’s tension discs need cleaning?

A: Uneven stitches, thread breakage, or difficulty adjusting tension settings are signs that your tension discs may be dirty. Cleaning them can resolve these issues and improve overall sewing machine performance. “How to Clean Tension Discs Sewing Machine“

Q5: Is it necessary to oil tension discs after cleaning my sewing machine?

A: No, it’s generally not necessary to oil tension discs. Refer to your machine’s manual; many modern machines have self-lubricating parts. If oiling is required, the manual will provide specific instructions on the type and quantity of oil to use. “How to Clean Tension Discs Sewing Machine“