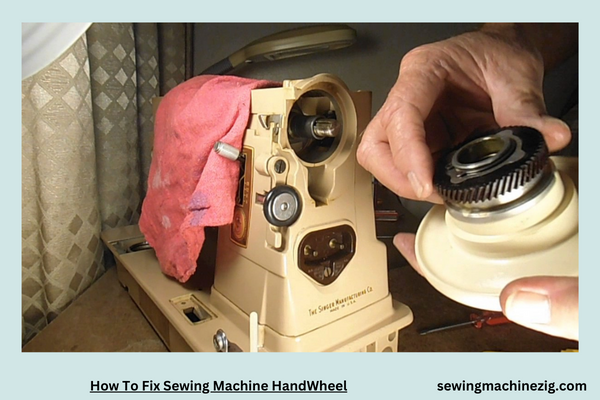

Navigating the intricate world of sewing machines can be both fascinating and challenging, especially when faced with the perplexing issue of a malfunctioning handwheel. Whether you’re a seasoned seamstress or a novice crafter, understanding how to fix the sewing machine handwheel is crucial for a seamless stitching experience.

In this guide,” How To Fix Sewing Machine HandWheel”, We’ll unravel the mysteries behind handwheel troubles and provide practical insights into troubleshooting. Get ready to dive into the mechanics of your sewing companion and emerge with the skills to tackle the common woes associated with the handwheel.

How To Fix Sewing Machine HandWheel Detailed Answer

Encountering a snag in your sewing machine journey? Fret not! This comprehensive guide will lead you through the intricate process of troubleshooting and fixing common issues with the sewing machine handwheel.

Whether you’re a seasoned seamstress or a novice, understanding the inner workings of this vital component is crucial for a smooth stitching experience.

Step 1:

Identify the Issue Begin by closely examining the handwheel and its adjacent components. Check for visible obstructions, tangled threads, or any signs of wear that might be causing the “How To Fix Sewing Machine HandWheel” problem.

Step 2:

Clean and Lubricate Address sluggish handwheel movement by delicately cleaning the handwheel and applying a small amount of sewing machine oil to ensure optimal performance.

Step 3:

Check for Thread Jam Thread jams are frequent culprits for handwheel issues. Remove the bobbin, throat plate, and any visible threads, carefully inspecting for tangles or lint that may hinder the “How To Fix Sewing Machine HandWheel” operation.

Step 4:

Tension Adjustment Correct tension settings are crucial for optimal handwheel performance. Consult your sewing machine manual to appropriately adjust the tension settings for the fabric being used, ensuring a well-balanced tension for both upper and lower threads.

Step 5:

Examine the Belt For belt-driven handwheels, inspect the belt for wear or damage. Replace any loose or damaged belts, following the manufacturer’s guidelines for seamless “How To Fix Sewing Machine HandWheel” operation.

Step 6:

Check for Loose Parts Examine the handwheel for loose screws or bolts that might cause wobbling or instability. Securely tighten any loose components to ensure a stable “How To Fix Sewing Machine HandWheel.”

Step 7:

Consult the Manual Each sewing machine is unique, so refer to your machine’s manual for specific troubleshooting tips and maintenance guidelines. Manufacturer insights can prove invaluable in addressing handwheel issues effectively.

Step 8:

Professional Assistance Persistent problems? Don’t hesitate to seek professional help. Reach out to the manufacturer’s customer support or consult a qualified sewing machine technician for expert “How To Fix Sewing Machine HandWheel” assistance.

Unlock the full potential of your sewing projects by mastering the art of fixing sewing machine handwheel issues. Follow this step-by-step guide to troubleshoot and resolve handwheel problems, ensuring a seamless and enjoyable sewing experience. Remember, a well-maintained handwheel is the key to unleashing your creativity in every stitch.

Why Does My Sewing Machine HandWheel Won’t Turn?

Embarking on a sewing project only to find your handwheel refusing to turn can be frustrating.

In this comprehensive guide, we’ll delve into the reasons behind the stubborn handwheel and provide a step-by-step troubleshooting process to get your sewing machine back in action. Whether you’re a seasoned seamstress or a beginner, understanding why your sewing machine handwheel won’t turn is crucial for a smooth stitching experience.

Step 1: Power Check

Before diving into intricate troubleshooting, ensure your sewing machine is properly powered. Verify that the power cord is securely connected, the power switch is on, and there are no electrical issues.

Step 2: Thread Tangles and Jams

A common culprit for a stuck handwheel is thread tangles or jams. Remove the bobbin, check the threading path, and inspect the bobbin area for any tangled threads or debris. Clear any obstructions to allow the handwheel to move freely.

Step 3: Bobbin Winding Mechanism

If the handwheel won’t turn during bobbin winding, ensure that you have disengaged the bobbin winding mechanism. Refer to your sewing machine manual for instructions on properly setting and releasing the bobbin winding mode.

Step 4: Machine Lubrication

Lack of lubrication can cause friction and hinder the handwheel’s movement. Apply a small amount of sewing machine oil to the moving parts as per the manufacturer’s recommendations. Be cautious not to over-oil, as excess oil can attract dust.

Step 5: Check for Loose Belts

For sewing machines with belt-driven handwheels, inspect the belt for any signs of wear or damage. A loose or damaged belt can impede the handwheel’s turning. Replace the belt following the manufacturer’s guidelines.

Step 6: Tension Adjustments

Incorrect tension settings can create resistance in the handwheel. Ensure that the upper and lower thread tensions are properly adjusted according to your sewing machine manual and the fabric you’re using.

Step 7: Broken or Bent Needle

A broken or bent needle can cause the handwheel to jam. Inspect the needle for any damage and replace it if necessary. Ensure that you’re using the correct needle type and size for your fabric.

Step 8: Check for Obstructions in the Feed Dogs

Inspect the feed dogs for any trapped fabric or debris. Clear any obstructions to ensure smooth fabric feeding, which can affect the handwheel’s movement.

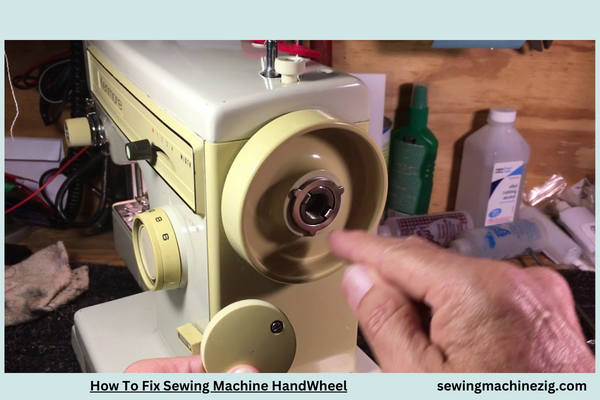

Step 9: Inspect the Handwheel Clutch

Some sewing machines have a disengaging clutch for winding the bobbin. Check if the handwheel clutch is engaged or disengaged according to your sewing machine manual.

Step 10: Professional Assistance

If the handwheel still won’t turn after following these steps, it’s advisable to seek professional assistance. Contact the manufacturer’s customer support or consult a qualified sewing machine technician for expert help.

By systematically addressing potential issues, you can troubleshoot and resolve the mystery of why your sewing machine’s handwheel won’t turn.

Remember to refer to your sewing machine manual for specific instructions and guidelines. With a bit of patience and the right troubleshooting steps, you’ll have your sewing machine back in working order, ready for your next creative project.”How To Fix Sewing Machine HandWheel“

HandWheel Does Not Turn Or is Tight

Discovering that your sewing machine’s handwheel does not turn or is tight can be a source of frustration for any seamstress.

In this comprehensive guide, we will explore the reasons behind this issue and provide a step-by-step troubleshooting process to help you get your sewing machine back in smooth operation. Whether you’re a seasoned sewing enthusiast or a novice, understanding and addressing why your handwheel is not turning or is tight is crucial for a seamless stitching experience.

Step 1: Power and Bobbin Check

Ensure that your sewing machine is properly powered and that there are no electrical issues. Additionally, inspect the bobbin area for any tangles or jams that might be causing the handwheel to resist turning.

Step 2: Thread Tension Adjustment

Incorrect thread tension can lead to a tight handwheel. Check and adjust both the upper and lower thread tensions according to your sewing machine manual and the fabric you’re using.

Step 3: Clean and Lubricate

Dirt and lack of lubrication can cause the handwheel to be tight. Carefully clean the handwheel and surrounding mechanisms, and apply a small amount of sewing machine oil to ensure smooth operation.

Step 4: Check for Obstructions

Inspect the feed dogs, the bobbin area, and the needle plate for any trapped fabric, lint, or debris. Clear any obstructions that might be hindering the handwheel’s movement.

Step 5: Inspect the Belt

For machines with a belt-driven handwheel, examine the belt for signs of wear or damage. A loose or damaged belt can result in a tight handwheel. Replace the belt following the manufacturer’s guidelines.

Step 6: Needle and Bobbin Compatibility

Ensure that you are using the correct needle type and size for your fabric. A bent or incorrect needle can lead to a tight handwheel. Additionally, check the bobbin to ensure it is compatible with your machine.

Step 7: Bobbin Winding Mechanism

If the handwheel is tight during bobbin winding, make sure the bobbin winding mechanism is disengaged. Follow your sewing machine manual for instructions on correctly setting and releasing the bobbin winding mode.

Step 8: Handwheel Clutch Engagement

Certain machines have a handwheel clutch that must be engaged for normal sewing. Check if the handwheel clutch is properly engaged according to your sewing machine manual.

Step 9: Professional Assistance

If the handwheel remains tight despite these efforts, it’s advisable to seek professional assistance. Contact the manufacturer’s customer support or consult a qualified sewing machine technician for expert help.

By systematically addressing potential issues, you can troubleshoot and resolve the challenge of a handwheel that does not turn or is tight. Remember to consult your sewing machine manual for specific instructions and guidelines. With patience and the right troubleshooting steps, you’ll soon have your sewing machine back in optimal condition, ready for your next creative endeavor.“How To Fix Sewing Machine HandWheel“

Conclusion

In the rhythmic dance of sewing, understanding How To Fix Sewing Machine HandWheel is a crucial step toward uninterrupted creativity. The handwheel, a linchpin in the sewing process, ensures the smooth orchestration of each stitch.

Knowing how to troubleshoot and rectify issues with the handwheel empowers the sewist to navigate challenges effortlessly. So, the next time your handwheel falters, see it not as a hindrance but as an opportunity to master the art of problem-solving and keep your sewing endeavors in perfect harmony.

FAQS

Q1: How can I fix a sewing machine handwheel that won’t turn?

A1: If your sewing machine’s handwheel is stuck, start by checking for thread jams in the bobbin area. Clean the machine, remove lint or debris, and lubricate moving parts. If the issue persists, the machine might be in the bobbin winding mode; disengage it by following the user manual.”How To Fix Sewing Machine HandWheel“

Q2: Why does my sewing machine handwheel feel tight?

A2: Tightness in the handwheel may result from thread tension issues, so rethread the machine, ensuring correct placement. Also, check for any obstructions in the bobbin area and adjust the tension settings as needed.

Q3: What should I do if the handwheel is turning but the needle isn’t moving?

A3: This could indicate a disengaged clutch or a broken drive belt. Consult your machine’s manual to locate and engage the clutch. If the belt is damaged, replace it following the manufacturer’s guidelines.

Q4: How do I troubleshoot a squeaky handwheel?

A4: Squeaking might be due to friction or lack of lubrication. Apply sewing machine oil to the handwheel’s moving parts, ensuring smooth rotation. If the noise persists, there might be worn-out components that need professional attention.

Q5: Can improper threading affect the handwheel’s performance?

A5: Yes, incorrect threading can lead to tension issues and affect the handwheel. Follow the threading instructions in your machine’s manual carefully, making sure the thread passes through all necessary guides and tension disks.

Q6: What if the handwheel becomes loose during sewing?

A6: A loose handwheel might indicate a loose set screw. Refer to your machine’s manual to locate the set screw and tighten it appropriately. Avoid over-tightening, as it may hinder the handwheel’s smooth operation.

Q7: Why is the handwheel not moving after I’ve changed the needle?

A7: After changing the needle, double-check for correct needle installation. Ensure the flat side faces the back and is inserted as far up as possible. If the handwheel is still not moving, there might be an issue with the needle clamp or timing, requiring professional inspection.