Embarking on the journey of sewing, a hiccup like timing issues can momentarily stall your creative flow. The question arises: “How To Fix Timing On Singer Sewing Machine?”

In this comprehensive guide, we navigate through the intricacies of Singer machine mechanics, providing a step-by-step elucidation on resolving timing glitches. As we unravel the inner workings, you’ll gain the expertise to realign your machine’s timing with precision, ensuring smooth stitches and uninterrupted creativity. Join us on this troubleshooting expedition, where we empower you to master the art of timing adjustments for your Singer sewing machine.

How To Fix Timing On Singer Sewing Machine Detailed Answer

A Singer sewing machine is a trusted companion in the realm of crafting and stitching, but when the timing goes awry, it can disrupt the smooth symphony of stitches.

In this detailed step-by-step guide, we will explore “How To Fix Timing On Singer Sewing Machine,” ensuring you navigate the intricacies of this restoration process with precision. Restoring the timing of your Singer sewing machine is akin to fine-tuning a musical instrument – it requires patience, attention to detail, and a systematic approach.

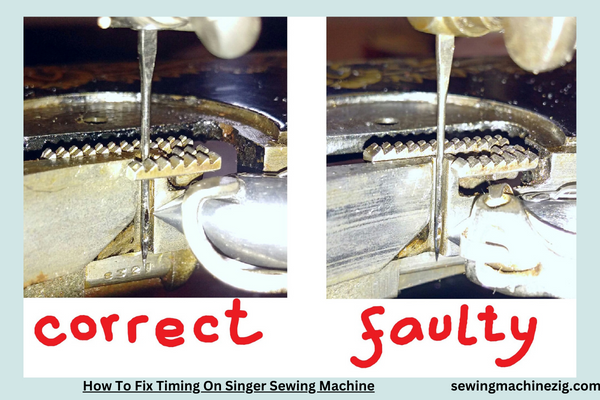

Step 1: Identify Timing Issues

Before delving into the restoration process, it’s essential to identify signs of timing issues. Uneven stitches, skipped stitches, or unusual noises during sewing can be indicative of timing problems. Examine the stitches on a test fabric to discern any irregularities that might suggest a misalignment in the timing mechanism.

Step 2: Gather Necessary Tools

To embark on the timing restoration journey, gather the necessary tools. You’ll need a small screwdriver, tweezers, a lint brush, your sewing machine’s manual, and, if possible, a flashlight to illuminate intricate areas.

Step 3: Disconnect the Power

Prioritize safety by turning off your Singer sewing machine and disconnecting it from the power source. This ensures a secure environment for the restoration process.

Step 4: Remove the Needle and Presser Foot

Start the physical disassembly by removing the needle and presser foot. Use the needle clamp screw to loosen and remove the needle, and disengage the presser foot according to your machine’s manual.

Step 5: Remove the Needle Plate and Bobbin Case

Next, remove the needle plate and the bobbin case to access the underlying mechanisms. Use your screwdriver to loosen the screws holding the needle plate in place and gently lift it away. Take note of any accumulated lint or debris in this area.

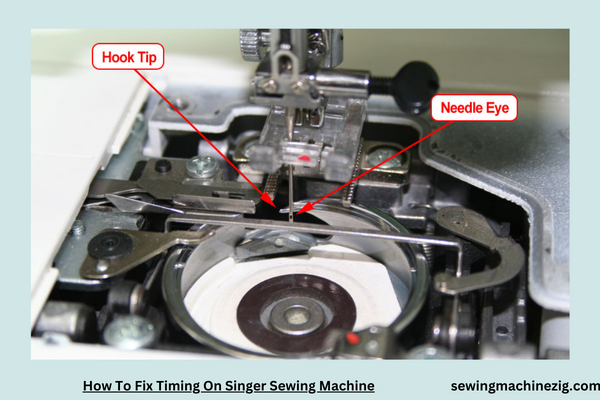

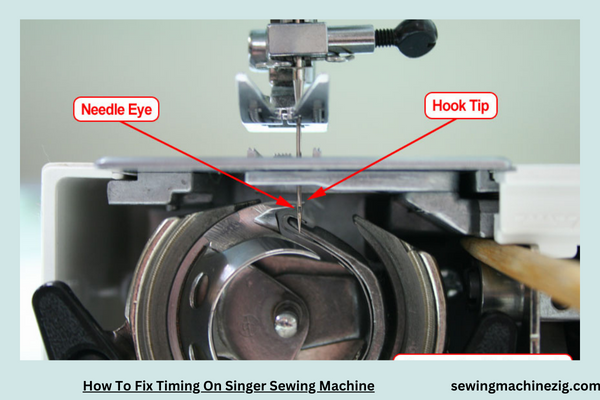

Step 6: Examine the Hook Timing

The hook timing is a critical element in the timing mechanism. Carefully observe the relationship between the needle and the hook. Ideally, the hook should pass behind the needle when the needle is on its upward stroke. If the hook collides with the needle, it indicates a timing issue.

Step 7: Adjust the Hook Timing

To adjust the hook timing, locate the set screw that holds the hook in place. Loosen this screw slightly, allowing for movement. Adjust the hook’s position to ensure it correctly passes behind the needle during its upward motion. Refer to your Singer sewing machine’s manual for precise instructions on hook timing adjustments.

Step 8: Align the Needle Bar

The needle bar must be in sync with the hook. If the needle bar is out of alignment, it can result in skipped stitches. Use your manual to identify the correct alignment and adjust the needle bar accordingly. Ensure it moves smoothly and aligns with the hook during the stitching process.

Step 9: Check the Needle Height

Proper needle height is crucial for the correct interaction between the needle and the hook. Use your manual to determine the correct needle height for your Singer sewing machine model. Adjust the needle if necessary to achieve the specified height.

Step 10: Reassemble the Bobbin Case and Needle Plate

With the timing adjustments made, carefully reassemble the bobbin case and needle plate. Ensure that all components are securely in place and that there is no resistance when moving the handwheel.

Step 11: Install a New Needle

Consider installing a new needle at this point, especially if the previous needle showed signs of damage. A fresh needle ensures optimal stitching performance.

Step 12: Test the Stitching

Perform a test stitch on a piece of scrap fabric to evaluate the effectiveness of the timing adjustments. Observe the stitches for uniformity and smoothness. If the stitches are even and consistent, it indicates successful timing restoration.

Step 13: Fine-Tune as Needed

If the test stitches reveal any remaining issues, fine-tune the timing adjustments. Repeat the process of examining the hook timing, needle bar alignment, and needle height. Make incremental adjustments until the stitches are precise and consistent.

Step 14: Consult Professional Help if Necessary

If, after thorough adjustments, the timing issues persist, or if you’re uncomfortable performing the adjustments yourself, consider consulting a professional sewing machine technician. They have the expertise to diagnose and rectify more complex timing problems.

Step 15: Regular Maintenance for Prevention

To prevent future timing issues, incorporate regular maintenance into your sewing routine. Keep the machine clean by removing lint and debris, change needles regularly, and follow the lubrication guidelines outlined in your Singer sewing machine’s manual.

Step 16: Troubleshooting Tips for Common Timing Issues

Understanding common timing issues can aid in troubleshooting. If you experience issues such as thread bunching, skipped stitches, or needle breakage, refer to your manual for specific troubleshooting tips related to timing. Addressing issues promptly can prevent more extensive problems.

Rediscovering Precision in Every Stitch

Restoring the timing on your Singer sewing machine is a gratifying journey of precision and craftsmanship.

By following this comprehensive guide, “How To Fix Timing On Singer Sewing Machine” you’ve equipped yourself with the knowledge to diagnose and rectify timing issues, ensuring that every stitch is a testament to the seamless synergy between the needle and hook. Approach the restoration process with patience and attention to detail, and your Singer sewing machine will once again be the harmonious conductor of your creative endeavors. Happy stitching!

How To Fix Hook Timing On Singer Sewing Machine

How To Fix Hook Timing On Singer Sewing Machine: Restoring Precision to Your Stitches

The rhythmic hum of a Singer sewing machine is a familiar and comforting sound for many enthusiasts, but when hook timing issues arise, that harmony can be disrupted.

In this extensive step-by-step guide, we’ll unravel the intricacies of “How To Fix Hook Timing On Singer Sewing Machine,” providing you with the tools and knowledge to restore precision to your stitches. Whether you’re a seasoned sewist or a novice, understanding and addressing hook timing problems is crucial for maintaining the optimal performance of your sewing machine.

Step 1: Diagnose Hook Timing Issues

Before diving into the restoration process, it’s essential to diagnose hook timing issues. Signs of hook timing problems include skipped stitches, thread bunching, or unusual noises during sewing. Carefully examine the stitches on a test fabric to identify irregularities that may suggest misaligned hook timing.

Step 2: Gather Necessary Tools and Materials

To embark on the journey of fixing hook timing, gather the necessary tools and materials. You’ll need a small screwdriver, tweezers, a lint brush, your Singer sewing machine’s manual, and, if possible, a flashlight to illuminate intricate areas. Having these tools at your disposal will facilitate a smooth and efficient restoration process.

Step 3: Disconnect the Power and Remove Needle/Presser Foot

Begin by ensuring safety – turn off your Singer sewing machine and disconnect it from the power source. Once done, remove the needle and presser foot to access the internal components more easily. Use the needle clamp screw to loosen and remove the needle and disengage the presser foot according to your machine’s manual.

Step 4: Access the Bobbin Case and Needle Plate

Proceed by removing the needle plate and the bobbin case to expose the hook and other essential components. Unscrew the needle plate carefully and lift it away, taking note of any lint or debris that may have accumulated in this area. Remove the bobbin case to access the hook mechanism.

Step 5: Understand the Hook Timing Mechanism

To effectively fix hook timing, it’s crucial to understand the hook timing mechanism. The hook, a rotating device beneath the bobbin case, engages with the needle to form stitches. Proper hook timing ensures that the hook catches the thread from the needle at the right moment.

Step 6: Align the Hook and Needle Timing

Examine the relationship between the hook and the needle. Ideally, the point of the hook should pass just behind the scarf (cutaway portion) of the needle as it rises. If the hook collides with the needle or fails to catch the thread properly, it indicates a timing issue.

Step 7: Loosen the Set Screw Holding the Hook

To adjust the hook timing, locate the set screw that holds the hook in place. Use a small screwdriver to gently loosen the set screw. This step allows you to move the hook into the correct position without resistance.

Step 8: Adjust the Hook Position

With the set screw loosened, carefully adjust the position of the hook. The goal is to align the hook so that it correctly catches the thread from the needle during the upward motion. Refer to your Singer sewing machine’s manual for specific instructions on the correct hook position.

Step 9: Re-tighten the Set Screw

Once the hook is correctly aligned, re-tighten the set screw securely. This ensures that the hook remains in the adjusted position during sewing. Avoid over-tightening, as it may cause unnecessary friction.

Step 10: Check Needle Bar Alignment

A misaligned needle bar can contribute to hook timing issues. Check the alignment of the needle bar using your Singer sewing machine’s manual as a guide. Ensure that the needle bar moves smoothly and aligns with the hook during the stitching process.

Step 11: Verify Needle Height

Proper needle height is essential for the interaction between the needle and the hook. Refer to your Singer sewing machine’s manual to determine the correct needle height for your model. Adjust the needle height if necessary to align with the specifications outlined in the manual.

Step 12: Reassemble the Bobbin Case and Needle Plate

With the adjustments made, carefully reassemble the bobbin case and needle plate. Ensure that all components are securely in place and that there is no resistance when moving the handwheel. The handwheel should turn freely without obstruction.

Step 13: Install a New Needle

Consider installing a new needle at this point, especially if the previous needle showed signs of damage. A fresh needle ensures optimal stitching performance and complements the corrected hook timing.

Step 14: Perform a Test Stitch

To verify the effectiveness of the hook timing adjustments, perform a test stitch on a piece of scrap fabric. Observe the stitches for uniformity and smoothness. If the stitches are even and consistent, it indicates successful hook timing restoration.

Step 15: Fine-Tune as Needed

If the test stitches reveal any remaining issues, fine-tune the hook timing adjustments. Repeat the process of examining the hook timing, needle bar alignment, and needle height. Make incremental adjustments until the stitches are precise and consistent.

Step 16: Consult Professional Help if Necessary

In cases where hook timing issues persist, or if you’re uncomfortable performing the adjustments yourself, consider seeking the expertise of a professional sewing machine technician. They have the knowledge and tools to diagnose and rectify more complex timing problems.

Step 17: Implement Regular Maintenance Practices

To prevent future hook timing issues, incorporate regular maintenance into your sewing routine. Remove lint and debris from the bobbin case and surrounding areas, change needles regularly, and follow the lubrication guidelines outlined in your Singer sewing machine’s manual.

Step 18: Troubleshooting Tips for Ongoing Maintenance

Understanding common issues related to hook timing can aid in ongoing troubleshooting and maintenance. If you encounter problems such as thread bunching or skipped stitches during regular use, consult your manual for specific troubleshooting tips related to hook timing.

Precision Restored, Creativity Unleashed

Fixing hook timing on your Singer sewing machine is a journey of precision and meticulous adjustments.

By following this comprehensive guide, you’ve equipped yourself with the knowledge to diagnose and rectify hook timing issues, ensuring that every stitch is a testament to the seamless coordination between the hook and needle. Approach the restoration process with patience and attention to detail, and your Singer sewing machine will once again be a reliable partner in bringing your creative visions to life. Happy stitching!

Conclusion

In conclusion, adeptly addressing “How To Fix Timing On Singer Sewing Machine” requires patience and precision. By following the detailed steps outlined, you can restore proper synchronization to your machine’s components. Resolving timing issues not only ensures smooth operation but also enhances the longevity of your Singer sewing machine.

Embrace the troubleshooting process, apply the recommended adjustments, and confidently breathe new life into your stitching companion, allowing it to continue crafting beautiful creations for years to come. “How To Fix Timing On Singer Sewing Machine“

FAQs for “How To Fix Timing On Singer Sewing Machine”

Q1: What are the signs that my Singer sewing machine may have timing issues?

A1: Signs include skipped stitches, thread breakage, or uneven stitches. If you notice these issues, it’s worth checking the timing. “How To Fix Timing On Singer Sewing Machine“

Q2: Can I fix timing issues on my Singer sewing machine without professional help?

A2: Yes, fixing timing issues is possible with careful adjustments. Follow the recommended steps in your machine’s manual or seek online tutorials. “How To Fix Timing On Singer Sewing Machine“

Q3: What tools do I need to fix timing on a Singer sewing machine?

A3: Common tools include a screwdriver, tweezers, and a lint brush. Specific models may require additional tools; consult your manual for details. “How To Fix Timing On Singer Sewing Machine“

Q4: How often should I check and adjust the timing on my Singer sewing machine?

A4: Check the timing if you notice stitching irregularities. Regular maintenance, such as cleaning and proper needle use, can help prevent timing issues. “How To Fix Timing On Singer Sewing Machine“

Q5: Can using the wrong needle cause timing issues on a Singer sewing machine?

A5: Yes, using a bent or incorrect needle can throw off the timing. Ensure you are using the correct needle size and type recommended for your machine. “How To Fix Timing On Singer Sewing Machine“

Q6: Is fixing timing a complex process on a Singer sewing machine?

A6: While it requires precision, fixing timing is manageable with patience. Follow the step-by-step instructions in your manual or consult online resources. “How To Fix Timing On Singer Sewing Machine“