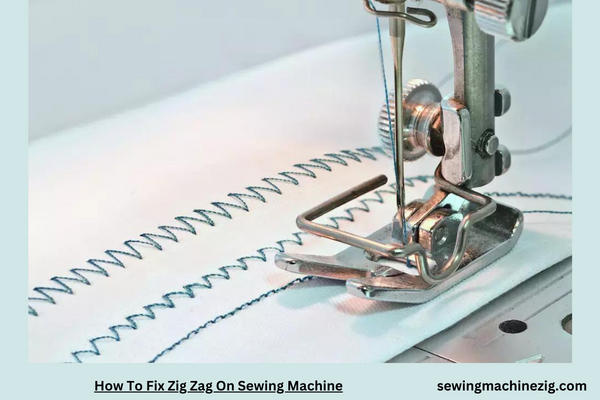

Navigating the intricate world of sewing machines, mastering the art of the zigzag stitch is paramount for versatile stitching. “How To Fix Zig Zag On Sewing Machine” becomes a crucial quest when facing stitching irregularities. Delving into troubleshooting is an essential skill for any avid sewist.

In this comprehensive guide, we dissect common issues affecting the zigzag stitch, offering insightful solutions to ensure your sewing machine operates seamlessly. From tension adjustments to examining needle placement, empowering yourself with the knowledge to rectify zigzag anomalies enhances your sewing experience, making each stitch a masterpiece.

How To Fix Zig Zag On Sewing Machine Detailed Answer

Encountering issues with the zig-zag stitch on your sewing machine can be a common challenge, but fear not – this step-by-step troubleshooting guide will assist you in identifying and rectifying the problem. Follow these comprehensive steps to get your zig-zag stitch back on track.

Understand the Zig-Zag Stitch:

- Begin by familiarizing yourself with the zig-zag stitch’s purpose. It’s a versatile stitch used for decorative edging, buttonholes, and various sewing applications.

Check Thread Tension:

- Incorrect thread tension is a frequent culprit for zig-zag issues. Ensure both upper and lower thread tensions are appropriately set. Consult your sewing machine manual for guidance on adjusting tension settings.

Inspect the Needle:

- A bent or dull needle can lead to stitching irregularities. Replace the needle with a new one, making sure it’s the right type for your fabric. A fresh, sharp needle is essential for a well-formed zig-zag stitch.

Evaluate Thread Quality:

- Low-quality or old thread can cause stitching problems. Use good-quality thread, and if your thread has been stored for an extended period, consider replacing it with fresh thread.

Clean the Machine:

- Dust and lint can accumulate in the machine, affecting its performance. Regularly clean the bobbin area, feed dogs, and other components. A clean machine promotes smooth stitching.

Check Bobbin Tension:

- Bobbin tension is critical for stitch formation. Ensure the bobbin is correctly threaded and placed following the machine’s threading diagram. Adjust the bobbin tension if necessary.

Evaluate Stitch Width and Length:

- Verify that the stitch width and length settings are appropriate for the zig-zag stitch. Adjust these settings based on your sewing project’s requirements.

Examine the Presser Foot:

- The presser foot should be compatible with the zig-zag stitch. Some machines have specific presser feet for zig-zagging. Using the correct foot ensures smooth stitching.

Check for Mechanical Issues:

- Inspect the machine for any visible mechanical issues. Ensure all parts are securely in place, and nothing is obstructing the smooth movement of the needle or other components.

Re-thread the Machine:

- Sometimes, simply re-threading the machine can resolve stitching problems. Follow the threading instructions in your manual, making sure the thread is correctly seated in the tension disks and through the guides.

Test on Scrap Fabric:

- Before continuing your project, test the zig-zag stitch on scrap fabric. This allows you to observe any remaining issues and make further adjustments if necessary.

Consult the Manual:

- If troubleshooting steps don’t resolve the problem, consult your sewing machine manual. Manuals often contain specific troubleshooting tips and information tailored to your machine model.

Consider Professional Help:

- If all else fails and you are unable to rectify the zig-zag issue, it might be time to seek professional help. Consult a qualified technician or take your sewing machine to a reputable service center for inspection and repair.

- By following this comprehensive troubleshooting guide, you should be well-equipped to identify and address issues with the zig-zag stitch on your sewing machine. Proceed step by step, and don’t hesitate to seek professional assistance if needed. Happy sewing!, “How To Fix Zig Zag On Sewing Machine“

How To Fix A Broken Zig-Zag Stitch On A Singer Heavy Duty

Encountering a broken zig-zag stitch on your Singer Heavy Duty sewing machine can be a frustrating setback, but fear not – this detailed step-by-step troubleshooting guide is designed to help you identify and resolve the issue. Follow these comprehensive steps to restore the functionality of the zig-zag stitch on your Singer Heavy Duty machine.

Understand the Zig-Zag Stitch:

- Begin by familiarizing yourself with the zig-zag stitch’s purpose. It is a versatile stitch used for decorative edging, buttonholes, and various sewing applications.

Identify the Issue:

- Before diving into troubleshooting, assess the nature of the broken zig-zag stitch. Determine if the issue is related to stitch irregularities, skipped stitches, or any other specific problem.

Check Thread Tension:

- Incorrect thread tension is a common cause of stitching issues. Ensure that both upper and lower thread tensions are appropriately set for the zig-zag stitch. Refer to your Singer Heavy Duty manual for guidance on adjusting tension settings.

Inspect the Needle:

- A bent, damaged, or dull needle can lead to a broken zig-zag stitch. Replace the needle with a new one, ensuring it is the correct type and size for your fabric. A sharp needle is crucial for achieving a well-formed zig-zag stitch.

Evaluate Thread Quality:

- Poor-quality or old thread can contribute to stitching problems. Use high-quality thread, and if your thread has been stored for an extended period, consider replacing it with fresh thread.

Clean the Machine:

- Dust and lint accumulation in the machine can hinder its performance. Regularly clean the bobbin area, feed dogs, and other components of your Singer Heavy Duty machine. A clean machine promotes smooth stitching.

Check Bobbin Tension:

- Proper bobbin tension is essential for a consistent zig-zag stitch. Ensure the bobbin is correctly threaded and placed according to the machine’s threading diagram. Adjust the bobbin tension if necessary.

Evaluate Stitch Width and Length:

- Confirm that the stitch width and length settings are appropriate for the zig-zag stitch. Adjust these settings based on your sewing project’s requirements.

Examine the Presser Foot:

- Ensure that the presser foot is suitable for zig-zag stitching. Some Singer Heavy Duty machines come with specialized presser feet for different stitches. Use the correct foot for smooth stitching.

Check for Mechanical Issues:

- Inspect the machine for any visible mechanical problems. Make sure all parts are securely in place, and nothing is obstructing the needle’s smooth movement or other components.

Re-thread the Machine:

- Re-threading the machine can sometimes resolve stitching problems. Follow the threading instructions in your Singer Heavy Duty manual, making sure the thread is correctly seated in the tension disks and through the guides.

Test on Scrap Fabric:

- Before continuing with your project, test the zig-zag stitch on scrap fabric. This allows you to observe any remaining issues and make further adjustments if necessary.

Consult the Manual:

- If the troubleshooting steps don’t resolve the problem, consult your Singer Heavy Duty sewing machine manual. Manuals often contain specific troubleshooting tips and information tailored to your machine model.

Consider Professional Help:

- If all else fails and you are unable to rectify the broken zig-zag stitch, it might be time to seek professional help. Consult a qualified technician or take your Singer Heavy Duty machine to a reputable service center for inspection and repair.

- By following this comprehensive troubleshooting guide, you should be well-equipped to identify and address issues with the broken zig-zag stitch on your Singer Heavy Duty sewing machine. Proceed step by step, and don’t hesitate to seek professional assistance if needed. Happy sewing!, “How To Fix Zig Zag On Sewing Machine“

Troubleshooting The Zig-Zag Stitch

Encountering issues with the zig-zag stitch on your sewing machine can be a common challenge, but fear not – this detailed step-by-step troubleshooting guide is designed to help you identify and resolve the issue. Follow these comprehensive steps to ensure a smooth and well-formed zig-zag stitch.

Understanding the Zig-Zag Stitch:

- Begin by understanding the zig-zag stitch’s purpose. It is a versatile stitch used for decorative edging, buttonholes, and various sewing applications.

Identify the Issue:

- Before diving into troubleshooting, assess the nature of the problem. Determine if the issue is related to stitch irregularities, skipped stitches, or any other specific problem.

Check Thread Tension:

- Incorrect thread tension is a common cause of zig-zag issues. Ensure that both upper and lower thread tensions are appropriately set for the zig-zag stitch. Refer to your sewing machine manual for guidance on adjusting tension settings.

Inspect the Needle:

- A bent, damaged, or dull needle can lead to problems with the zig-zag stitch. Replace the needle with a new one, ensuring it is the correct type and size for your fabric. A sharp needle is crucial for achieving a well-formed zig-zag stitch.

Evaluate Thread Quality:

- Poor-quality or old thread can contribute to stitching problems. Use high-quality thread, and if your thread has been stored for an extended period, consider replacing it with fresh thread.

Clean the Machine:

- Dust and lint accumulation in the machine can hinder its performance. Regularly clean the bobbin area, feed dogs, and other components of your sewing machine. A clean machine promotes smooth stitching.

Check Bobbin Tension:

- Proper bobbin tension is essential for a consistent zig-zag stitch. Ensure the bobbin is correctly threaded and placed according to the machine’s threading diagram. Adjust the bobbin tension if necessary.

Evaluate Stitch Width and Length:

- Confirm that the stitch width and length settings are appropriate for the zig-zag stitch. Adjust these settings based on your sewing project’s requirements.

Examine the Presser Foot:

- Ensure that the presser foot is suitable for zig-zag stitching. Some machines come with specialized presser feet for different stitches. Use the correct foot for smooth stitching.

Check for Mechanical Issues:

- Inspect the machine for any visible mechanical problems. Make sure all parts are securely in place, and nothing is obstructing the needle’s smooth movement or other components.

Re-thread the Machine:

- Re-threading the machine can sometimes resolve stitching problems. Follow the threading instructions in your sewing machine manual, making sure the thread is correctly seated in the tension disks and through the guides.

Test on Scrap Fabric:

- Before continuing with your project, test the zig-zag stitch on scrap fabric. This allows you to observe any remaining issues and make further adjustments if necessary.

Consult the Manual:

- If the troubleshooting steps don’t resolve the problem, consult your sewing machine manual. Manuals often contain specific troubleshooting tips and information tailored to your machine model.

Consider Professional Help:

- If all else fails and you are unable to rectify the zig-zag stitch issue, it might be time to seek professional help. Consult a qualified technician or take your sewing machine to a reputable service center for inspection and repair.

- By following this comprehensive troubleshooting guide, you should be well-equipped to identify and address issues with the zig-zag stitch on your sewing machine. Proceed step by step, and don’t hesitate to seek professional assistance if needed. Happy sewing!

Conclusion

In conclusion, mastering the art of sewing requires a keen understanding of troubleshooting techniques. This step-by-step guide on ‘How To Fix Zig Zag On Sewing Machine‘, empowers sewists to navigate through common issues, ensuring a seamless stitching experience.

By addressing aspects such as thread tension, needle condition, and machine cleanliness, enthusiasts can now confidently troubleshoot their machines. Remember, a well-maintained sewing machine opens the door to endless creative possibilities, and this guide serves as a valuable resource for achieving precisely that.

FAQS

Q1: What are the common issues that lead to a zig-zag malfunction on my sewing machine?

A1: Zig-zag issues often result from issues like incorrect thread tension, a bent needle, or improper machine settings. Identifying the specific problem is crucial for effective troubleshooting.”How To Fix Zig Zag On Sewing Machine“

Q2: Can I fix the zig-zag problem on my sewing machine without professional help?

A2: Yes, many zig-zag issues can be resolved at home. This FAQ guide on ‘How to Fix Zig Zag on Sewing Machine’ provides step-by-step instructions to help you troubleshoot and resolve the problem.”How To Fix Zig Zag On Sewing Machine“

Q3: What role does thread tension play in causing zig-zag irregularities, and how can I adjust it?

A3: Incorrect thread tension can lead to zig-zag issues. Refer to your sewing machine manual for guidance on adjusting both upper and lower thread tensions to achieve the desired zig-zag stitch.”How To Fix Zig Zag On Sewing Machine“

Q4: Is a bent or damaged needle a common cause of zig-zag problems, and how can I replace it?

A4: Yes, a bent needle can affect the zig-zag stitch. Refer to your machine’s manual for instructions on safely replacing the needle with the correct type and size for your fabric.

Q5: Can using poor-quality thread contribute to zig-zag issues, and how can I choose the right thread?

A5: Yes, low-quality thread can lead to stitching problems. Choose a high-quality thread suitable for your fabric and project. Ensure the thread is compatible with your sewing machine.“How To Fix Zig Zag On Sewing Machine“

Q6: How often should I clean my sewing machine to prevent zig-zag problems?

A6: Regular cleaning is essential to prevent dust and lint buildup that can affect the machine’s performance. Follow your machine’s manual for instructions on proper cleaning and maintenance.“How To Fix Zig Zag On Sewing Machine“