A sewing machine can be a helpful tool to have at home, especially for those who enjoy creating and repairing clothing or other fabric items. However, one of the most frustrating problems that a sewer can face is when their machine jams after only a few stitches. Not only can this be time-consuming, but it can also lead to a loss of enthusiasm for the project at hand. In this article, we will discuss sewing machine jams after few stitches.

Why Your Sewing Machine Keeps Jamming & How to Fix It

There are a few different reasons why a sewing machine jams after a few stitches, and it can be difficult to pinpoint the exact cause without some troubleshooting. In some cases, the issue may be related to the tension of the thread, while in other cases it may be due to a problem with the needle or bobbin. It’s essential to identify the cause of the problem and address it promptly to prevent further frustration and ensure the sewing machine is working correctly.

Singer Sewing Machine Jams After Few Stitches

Singer sewing machines are renowned for their reliability and performance. However, even the most reliable machines can sometimes experience issues that cause them to jam after just a few stitches. Sewing machine jams can be frustrating, especially when you’re in the middle of a project. In this article, we’ll explore some common causes of singer sewing machine jams after few stitches.

Let’s explore some of the common reasons why a sewing machine jams after few stitches and provide some tips on how to troubleshoot and fix the issue.

Here are some common problems and solutions for a sewing machine jams after few stitches:

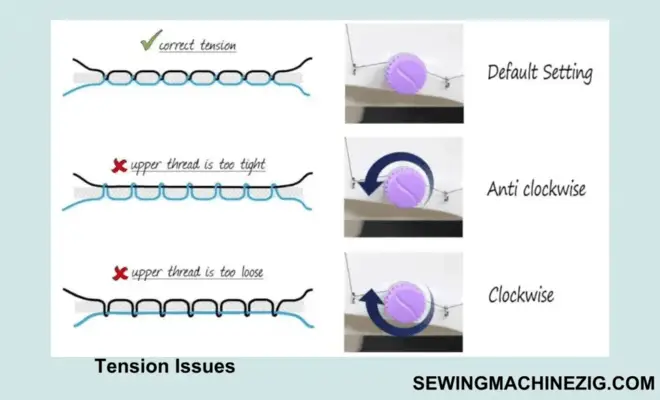

1: Tension Issues:

If the thread tension is too tight, the thread can become stuck in the fabric, causing the machine to jam. Similarly, if the thread tension is too loose, the thread can become tangled in the bobbin, leading to a jam.

Solution: Adjust the thread tension according to the fabric type and thickness. Adjust the thread tension. Start with the recommended settings and make small adjustments until you achieve the desired results.

2: Needle Problems:

A bent needle can cause the thread to break or get stuck in the fabric, while a dull needle can struggle to penetrate the fabric, leading to jams.

Solution: Replace the needle regularly, especially if you’re sewing on thicker fabrics or using the machine frequently. Also, make sure to use the correct needle type and size for the fabric you’re sewing.

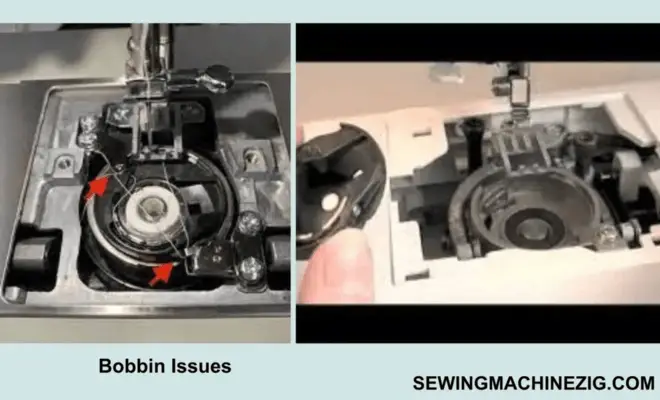

3: Bobbin Issues:

If the bobbin is not inserted correctly, or if the thread is not wound correctly on the bobbin, it can cause the machine to jam. Additionally, if the bobbin case is damaged or worn, it can lead to jams.

Solution: Ensure that the bobbin is inserted correctly and the thread is wound evenly. If the bobbin case is damaged, replace it with a new one.

4: Machine Maintenance:

Dust and lint can accumulate inside the machine, causing it to malfunction.

Solution: Clean the machine regularly and lubricate the moving parts as per the manual’s recommendations.

By troubleshooting and fixing the issues mentioned above, you can prevent your sewing machine from jamming after a few stitches. I hope this resolves your issue if it still continues to sewing machine jams after few stitches follow the below solution.

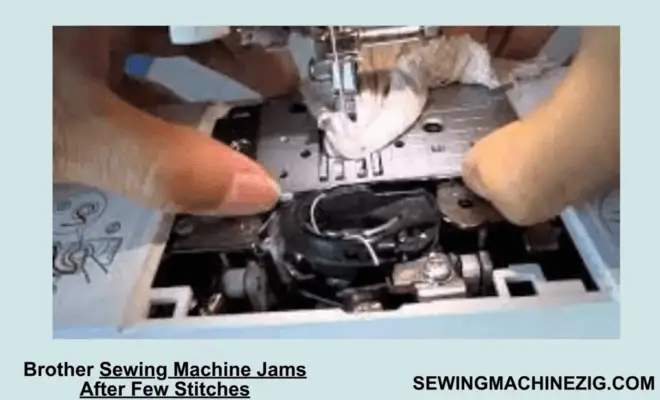

Brother Sewing Machine Jams After Few Stitches

Sewing is a wonderful hobby and a useful skill, but it can be frustrating when your sewing machine jams after just a few stitches. One common cause of this issue is improper threading, but there could be several other reasons why your Brother sewing machine is jamming. In this article, we will explore some of the possible causes of a Brother sewing machine jams after few stitches and provide some tips to help you troubleshoot and fix the problem.

1: Improper threading:

Ensure that the thread is correctly threaded through all the machine’s components.

Solution: Rethread the machine, ensuring that the thread passes through all the necessary loops and guides.

2: Tension issues:

Adjust the thread tension to ensure it is set correctly for the type of fabric you are using.

Solution: Use the machine’s tension adjustment dial to adjust the upper thread tension. If the tension is too tight, the thread will break. If the tension is too loose, the thread will bunch up and cause a jam.

3: Needle issues:

Replace the needle if it is damaged or bent.

Solution: Use the right size and type of needle for the fabric you are using. If the needle is dull, bent, or broken, it will not pick up the thread correctly and can cause a jam.

4: Incorrect needle size:

Use the correct needle size for the fabric you are working with.

Solution: Choose the appropriate needle size based on the weight and type of fabric you are using. A too-small needle can cause the thread to break, while a too-large needle can cause fabric damage.

5: Bobbin issues:

Check that the bobbin is correctly inserted and wound.

Solution: Make sure the bobbin is wound tightly and inserted correctly.

6: Bobbin tension issues:

Adjust the bobbin tension to ensure it is set correctly.

Solution: Use the machine’s bobbin tension adjustment screw to adjust the bobbin tension. If the tension is too loose, the bobbin thread will loop and tangle, causing a jam. If the tension is too tight, the bobbin thread will break.

7: Incorrect stitch length:

Ensure the stitch length is appropriate for the fabric you are working with.

Solution: Adjust the stitch length to the appropriate setting for the fabric you use. If the stitch length is too short, it can cause the thread to bunch up and jam.

8: Sewing speed:

Slow down the sewing speed to avoid jams.

Solution: Sew slowly, especially when working with thick or difficult fabrics. This can help prevent the needle from jamming and ensure a smooth stitch.

9: Wrong foot or plate:

Use the correct presser foot or a needle plate for the stitch you are using.

Solution: Choose the appropriate presser foot or a needle plate for the type of stitch you are making. Using the wrong foot or plate can cause the fabric to jam, especially when making decorative stitches.

By addressing these issues, you can troubleshoot and fix the problem of your Brother sewing machine jamming after just a few stitches, and enjoy uninterrupted sewing for your projects. This is also a part of sewing machine jams after few stitches and it’s really a header of issue that multiple solutions is written in this article for you.

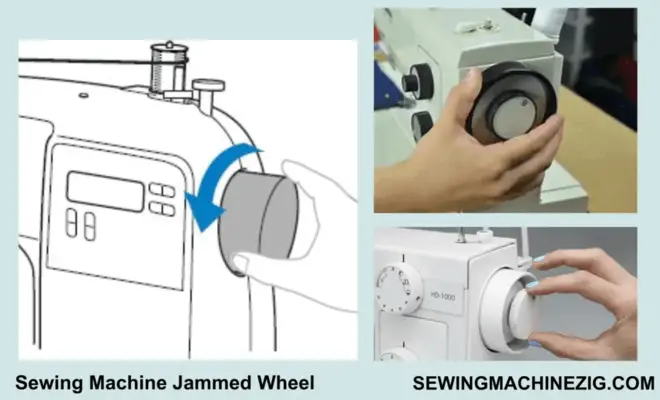

Sewing Machine Jammed Wheel

If your sewing machine’s hand wheel is jammed, you may find that it’s difficult or even impossible to turn the wheel. This can be frustrating, especially if you’re in the middle of a project. A jammed handwheel can be caused by a number of issues, from tangled thread to a malfunctioning mechanism. In this article, we’ll explore some common causes of sewing machine jams after few stitches and sewing machine jammed handwheel and provide solutions to help you troubleshoot and fix the problem.

1: Tangled Thread:

The most common cause of a jammed handwheel is a tangled thread.

Solution: Gently remove the fabric from the machine and remove any tangled thread. If the thread is too tangled, cut it and start again.

2: Dirt and Debris:

Dirt and debris can accumulate in the machine, causing the handwheel to jam.

Solution: Clean the machine by removing the needle plate and bobbin case. Use a soft brush or vacuum cleaner to remove any dirt or debris.

3: Wrong Needle Size:

Using the wrong needle size for the fabric can cause the handwheel to jam.

Solution: Ensure you are using the correct needle size and type for the fabric you are using.

4: Old Needle:

An old, worn-out needle can also cause the handwheel to jam.

Solution: Replace the needle with a new one.

5: Tension Issues:

Incorrect tension settings can cause the handwheel to jam.

Solution: Adjust the tension settings on the machine to ensure they are correctly set for the fabric you are using.

6: Bobbin Issues:

Problems with the bobbin can cause the handwheel to jam.

Solution: Check that the bobbin is correctly inserted and that the thread is correctly wound around it.

7: Timing Issue:

The timing of the machine may be off, causing the handwheel to jam.

Solution: If you suspect that the timing of the device is off, it is best to take it to a professional for repair.

8: Loose Parts:

Loose parts in the machine can cause the handwheel to jam.

Solution: Check the machine’s manual to ensure all parts are correctly attached and tightened.

9: Machine Malfunction:

A malfunctioning machine can also cause the handwheel to jam.

Solution: If none of the above solutions work, it is best to take the machine to a professional for repair.

10: Rust:

Rust can cause the handwheel to jam if it has accumulated on the metal parts of the machine.

Solution: Remove rust from the metal parts of the machine with a rust remover.

By addressing these issues, you can troubleshoot and fix the problem of a jammed handwheel on your sewing machine, and get back to sewing smoothly. I hope now you are mostly aware of sewing machine jams after few stitches and how to handle this issue and prevent it from happening if the problem is underneath the machine then read and follow the below article.

Sewing Machine Keeps Jamming Underneath

If your sewing machine keeps jamming underneath, it can be frustrating and can bring your sewing projects to a halt. There could be several reasons why the thread is getting jammed underneath the fabric, and understanding the root cause is key to resolving the issue. In this article, we’ll explore some common reasons why your sewing machine jams after few stitches underneath and provide solutions to help you troubleshoot and fix the problem.

1: Thread Tension Issues:

Uneven or incorrect thread tension can cause the thread to get jammed underneath the fabric.

Solution: Adjust the thread tension and re-thread the machine, ensuring that the thread is correctly placed in the tension disks.

2: Needle Issues:

A damaged or worn-out needle can cause the thread to break or get jammed.

Solution: Replace the needle with a new one and ensure that it is correctly inserted and tightened.

2: Bobbin Issues:

Problems with the bobbin can cause the thread to get jammed underneath the fabric.

Solution: Ensure that the bobbin is correctly inserted and that the thread is correctly wound around it.

3: Dirty or Lint-Filled Machine:

A build-up of lint or dirt can cause the machine to jam.

Solution: Clean the machine regularly, including the bobbin area, feed dogs, and shuttle race.

4: Incorrect Needle Size:

Using the wrong needle size for the fabric can cause the thread to get jammed underneath the fabric.

Solution: Ensure that you are using the correct needle size for the fabric you are working with.

5: Improperly Inserted Bobbin:

An improperly inserted bobbin can cause the thread to jam.

Solution: Ensure that the bobbin is inserted correctly and that the thread is correctly wound around it.

6: Incorrect Threading:

Incorrect threading can cause the thread to get jammed underneath the fabric.

Solution: Re-thread the machine, ensuring that the thread is correctly placed through all the necessary guides and tension discs.

7: Worn-Out Feed Dogs:

Worn-out feed dogs can cause the fabric to move unevenly, leading to jams.

Solution: Replace the feed dogs or have them serviced by a professional.

By troubleshooting and fixing these major problems, you should be able to resolve most issues with your sewing machine jamming underneath. I hope now you are mostly aware of sewing machine jams after few stitches and how to handle this issue and prevent it from happening if the problem is the bobbin area singer machine then read and follow the below article.

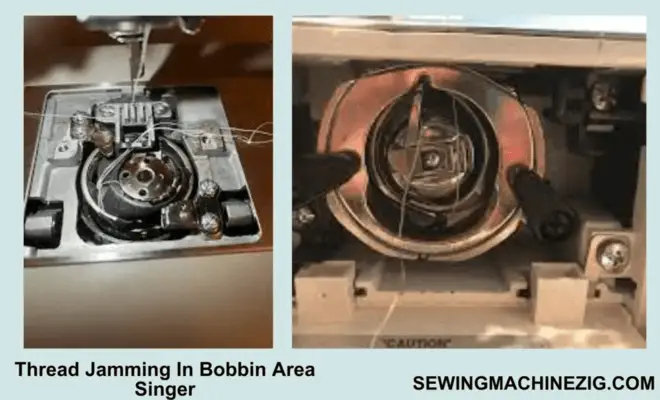

Thread Jamming In Bobbin Area Singer

If you own a Singer sewing machine, you may encounter a common issue known as “thread jamming in the bobbin area.” This problem occurs when the thread gets tangled or stuck in the area underneath the needle plate, where the bobbin is located. This can cause frustration and delay in your sewing projects, especially if you’re not familiar with the proper techniques to address the issue.

Fortunately, there are several steps you can take to prevent sewing machine jams after few stitches in the bobbin area and troubleshoot the problem when it occurs. In this article, we’ll explore some of the common causes of thread jamming and provide tips on how to fix it.

Top Thread Jamming In Bobbin Area

If the top thread is jamming in the bobbin area of your sewing machine or the sewing machine jams after a few stitches, there could be several possible causes. Here are some common reasons why this might be happening, and what you can do to fix it:

1: Incorrect threading:

Check that the top thread is correctly threaded through the machine’s tension discs and the needle. If the thread is not properly seated in the tension discs, it can cause the thread to bunch up and jam in the bobbin area. Re-thread the machine, making sure to follow the threading path shown in your machine’s manual.

2: Damaged or worn needle:

A damaged or worn needle can cause the top thread to break or jam in the bobbin area. Make sure to use the correct type of needle for the fabric you’re sewing and replace it regularly, especially if you’re sewing through thick or heavy fabrics.

3: Tension problems:

If the tension on the machine is too loose, the top thread can get pulled down into the bobbin area and jam. Check that the upper and lower tension settings are correct for the type of fabric and thread you’re using.

4: Dirty or damaged bobbin case:

If the bobbin case is dirty or damaged, it can cause the thread to jam. Remove the bobbin case and clean it thoroughly, removing any dirt or debris that may have accumulated. If the case is damaged, replace it with a new one.

5: Incorrect bobbin size:

Make sure that you’re using the correct size and type of bobbin for your machine. Using the wrong size bobbin can cause the thread to jam or break.

By troubleshooting these common issues, you can prevent the top thread from jamming in the bobbin area of your sewing machine and keep your sewing projects running smoothly. I hope now you are mostly aware of sewing machine jams after few stitches and how to handle this issue and prevent it from happening if the problem is backstitch jamming then read and follow the below article.

Why Does My Sewing Machine Jam When I Backstitch

A sewing machine jams after few stitches.If your sewing machine is jamming when you backstitch, it can be frustrating and cause delays in your sewing projects. Here are ten possible reasons why your sewing machine jams after a few stitches during backstitching, and some solutions to try:

1: Machine speed:

Sewing too quickly or too slowly during backstitching can cause the machine to jam. Try adjusting the speed of your machine and see if that helps prevent jamming.

Solution: Slow down or speed up your sewing machine as necessary to find the right speed for your fabric and thread.

2: Buildup of thread or lint:

Accumulated thread or lint in the bobbin area can cause the machine to jam during backstitching. Regularly clean the machine, especially the bobbin area, to prevent this from happening.

Solution: Clean your sewing machine regularly to remove any lint or thread buildup.

3: Bent or dull needle:

A bent or dull needle can cause the machine to jam during backstitching. Check the needle and replace it if necessary.

Solution: Inspect the needle and replace it if it’s bent or dull.

4: Bobbin tension issues:

Incorrect bobbin tension can cause the machine to jam during backstitching. Check that the bobbin thread is properly threaded through the case and tension spring.

Solution: Adjust the bobbin tension as needed. If the bobbin thread is too loose or too tight, adjust the tension screw on the bobbin case.

5: Worn or damaged feed dogs:

Worn or damaged feed dogs can cause the fabric to move unevenly and cause the machine to jam during backstitching.

Solution: Inspect the feed dogs and replace them if they are worn or damaged.

6: Improper presser foot pressure:

Incorrect presser foot pressure can cause the fabric to move unevenly and cause the machine to jam during backstitching.

Solution: Adjust the presser foot pressure as needed. Most machines have a dial or knob that can be turned to adjust the pressure.

7: Incorrect stitch length:

Using an incorrect stitch length can cause the machine to jam during backstitching. Make sure you’re using the correct stitch length for your fabric and thread.

Solution: Adjust the stitch length as needed. If the stitch length is too long or too short, adjust the stitch length dial on your machine.

By troubleshooting these common issues, you can prevent your sewing machine from jamming during backstitching and ensure that your sewing projects are completed smoothly. These are the solution related to sewing machine jams after few stitches.

Conclusion:

A sewing machine jams after few stitches can be caused by a variety of factors. Some of the most common causes include incorrect needle type or size, improper threading, tension issues, the buildup of thread or lint, and worn or damaged feed dogs.

To prevent these issues, it’s important to use the correct needle and thread, thread the machine properly, adjust the tension settings, clean the machine regularly, and inspect and replace any worn or damaged parts. By taking these steps, you can ensure that your sewing machine runs smoothly and produces high-quality stitches every time. I hope now you have read and understand all the issues relatingsewing machine jams after few stitches and their solutions and how to prevent them from happening.

FAQs:

Here are some frequently asked questions about sewing machine jams after few stitches, along with detailed answers:

Q 1: What causes a sewing machine jams after few stitches?

A: A sewing machine can jam after a few stitches due to a variety of factors, such as incorrect needle type or size, improper threading, tension issues, the buildup of thread or lint, worn or damaged feed dogs, and more.

Q 2: How can I prevent my sewing machine from jamming after a few stitches?

A: To prevent your sewing machine from jamming after a few stitches, make sure to use the correct needle and thread, thread the machine properly, adjust the tension settings, clean the machine regularly, and inspect and replace any worn or damaged parts.

Q 3: Can using the wrong needle cause my sewing machine to jam?

A: Yes, using the wrong needle type or size can cause your sewing machine to jam. Make sure to use the correct needle for your fabric and thread to avoid this issue.

Q 4: How can I adjust the tension on my sewing machine?

A: Most sewing machines have a tension dial or knob that can be turned to adjust the tension. Refer to your machine’s manual for specific instructions on how to adjust the tension.

Q 5: How often should I clean my sewing machine?

A: It’s a good idea to clean your sewing machine after every project or at least once a week if you use it frequently. Regular cleaning can help prevent thread and lint buildup, which can cause the machine to jam.

Q 6: Can worn or damaged feed dogs cause my sewing machine to jam?

A: Yes, worn or damaged feed dogs can cause the fabric to move unevenly and cause the machine to jam. Inspect the feed dogs regularly and replace them if they are worn or damaged.