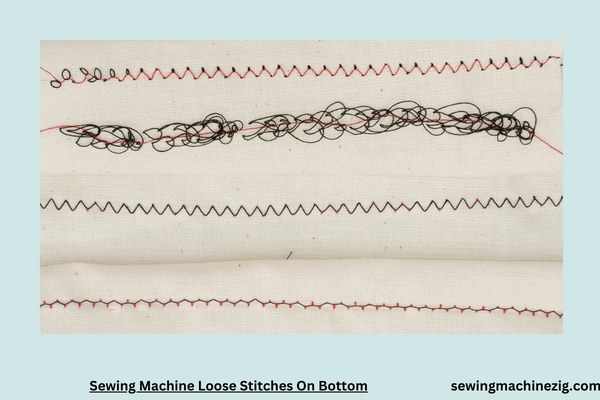

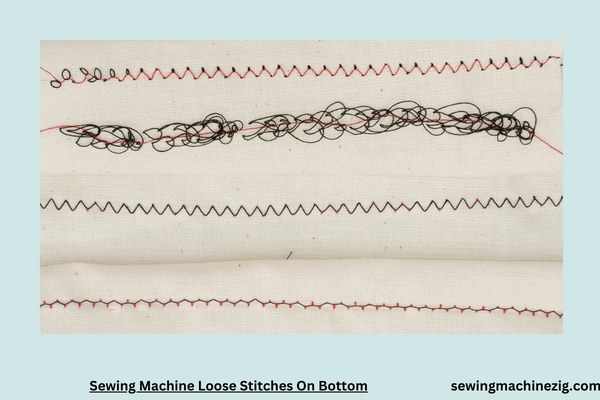

Ever experienced the frustration of your sewing machine creating chaos with loose stitches on the bottom side of your fabric? It’s a common woe, and I get it—we’ve all been there, battling the unraveling thread nightmare. But fear not!

In this guide, “Sewing Machine Loose Stitches On Bottom” I’ll unravel the mystery behind sewing machine loose stitches, providing you with straightforward solutions. Let’s turn that frustration into seamless stitching joy as we troubleshoot the issue and get your sewing machine back on track. Say goodbye to the bottom-side stitch struggle, and hello to a smooth sewing experience.

Sewing Machine Loose Stitches On Bottom Detailed Answer

Understanding the Anatomy of a Stitch:

Before diving into the intricacies of troubleshooting, let’s take a moment to appreciate the fundamental components of a stitch. A stitch is a delicate interplay between the upper thread, the lower thread (bobbin thread), and the fabric. When tension in this delicate dance falters, loose stitches can manifest on the underside of your project.

Common Culprits of Loose Stitches on the Bottom:

- Bobbin Tension:

- Symptom: Loose stitches on the bottom can often be attributed to improper bobbin tension.

- Solution: Adjust the bobbin tension according to your sewing machine’s manual. Experiment with small adjustments until the stitches appear balanced.

- Upper Thread Tension:

- Symptom: If the upper thread tension is too loose, it can result in slack on the bottom.

- Solution: Check the upper thread tension dial on your machine. Increase the tension gradually until the stitches achieve the desired tightness.

- Thread Compatibility:

- Symptom: Mismatched threads in the bobbin and upper thread can lead to uneven tension.

- Solution: Ensure that the threads are compatible in weight and type. Consistent thread quality contributes to uniform tension.

- Thread Path Issues:

- Symptom: Incorrect threading or tangled threads can disrupt the stitching process.

- Solution: Re-thread your sewing machine carefully, following the machine’s threading guide. Clear any thread snarls or knots that may impede smooth thread flow.

- Bobbin Winding:

- Symptom: Unevenly wound bobbins can result in irregular tension.

- Solution: Wind the bobbin evenly, ensuring a smooth and consistent winding process. Check the bobbin tension as well.

- Needle Issues:

- Symptom: A dull, bent, or improperly inserted needle can impact stitching quality.

- Solution: Replace the needle regularly and ensure it is compatible with your fabric. Insert the needle with the flat side facing the back of the machine.

- Machine Maintenance:

- Symptom: Accumulated lint or debris can hinder the machine’s smooth operation.

- Solution: Regularly clean your sewing machine, removing lint and debris. Lubricate the machine as recommended in the manual.

- Fabric Type and Weight:

- Symptom: Heavy fabrics may require different tension settings than lighter ones.

- Solution: Adjust the tension settings based on the fabric you are working with. Test on a fabric scrap before starting your project.

Troubleshooting and Adjustments:

- Tension Test:

- How: Sew a test fabric swatch with a variety of stitches. Observe the stitches on both sides. Adjust the tension settings incrementally until you achieve balanced stitches.

- Bobbin Check:

- How: Inspect the bobbin area for any loose threads or debris. Ensure the bobbin is correctly inserted and wound evenly.

- Needle Examination:

- How: Examine the needle for any signs of damage, bending, or dullness. Replace the needle if needed.

- Thread Re-Thread:

- How: Rethread both the upper thread and the bobbin thread. Follow the machine’s threading guide meticulously.

- Bobbin Case Inspection:

- How: Check the bobbin case for any nicks, rough spots, or damage. Replace the bobbin case if necessary.

- Machine Lubrication:

- How: Lubricate your sewing machine according to the manufacturer’s instructions. Ensure smooth mechanical operation.

Preventive Measures for Future Projects:

- Consistent Thread Quality:

- Why: High-quality, compatible threads contribute to smooth stitching.

- How: Invest in reliable threads and ensure both upper and bobbin threads are of similar quality.

- Regular Maintenance:

- Why: Preventive care keeps your machine in optimal condition.

- How: Schedule regular cleaning sessions for your sewing machine. Remove lint, oil moving parts, and check for any signs of wear.

- Needle Awareness:

- Why: Needles play a crucial role in stitching quality.

- How: Use the right needle for your fabric type and change it regularly. Inspect needles for any signs of damage before starting a project.

- Tension Adjustment Know-How:

- Why: Understanding tension settings is key to achieving desired stitch quality.

- How: Familiarize yourself with your machine’s tension adjustments. Practice on scrap fabric to fine-tune tension before beginning a project.

Summary: Stitching Success Unveiled

Embarking on sewing adventures becomes a joyous affair when armed with the knowledge to conquer challenges. Loose stitches on the bottom need not be a source of frustration. Armed with troubleshooting insights and preventive measures, you’re equipped to turn every sewing project into a masterpiece.

Remember, the art of sewing is not just about creating; it’s about the mastery of your craft and the satisfaction of watching your creations come to life, stitch by perfect stitch. Happy sewing! “Sewing Machine Loose Stitches On Bottom“

Causes Of Loose Sewing Machine Stitches

Understanding the Anatomy of a Stitch:

Before delving into the causes of loose stitches, let’s grasp the basics. A stitch is a delicate collaboration between the upper thread and the bobbin thread, intertwining through the fabric. When harmony is disrupted, loose stitches emerge, creating a puzzle that we are here to solve.

Common Culprits of Loose Stitches:

- Tension Troubles:

- Symptom: Uneven tension between the upper thread and the bobbin thread can result in loose stitches.

- Solution: Adjust the tension settings on your sewing machine. Experiment with small increments until you achieve a balanced stitch appearance.

- Incorrect Threading:

- Symptom: Mishandling the threading process can lead to loose stitches.

- Solution: Revisit your sewing machine’s manual and rethread both the upper thread and the bobbin thread, following the correct paths. Ensure there are no missed loops or tangles.

- Bobbin Woes:

- Symptom: Issues with the bobbin, such as uneven winding or improper insertion, can cause stitching problems.

- Solution: Wind the bobbin evenly and ensure it is correctly inserted into the bobbin case. Check for any debris or lint in the bobbin area.

- Needle Matters:

- Symptom: A dull, bent, or incorrectly inserted needle can result in loose stitches.

- Solution: Change the needle regularly, ensuring it is the appropriate type and size for your fabric. Insert the needle with the flat side facing the back of the machine.

- Thread Quality and Compatibility:

- Symptom: Mismatched or low-quality threads can affect stitch formation.

- Solution: Invest in high-quality threads, and ensure both the upper and bobbin threads are compatible in type and weight.

- Machine Maintenance Neglect:

- Symptom: Accumulated lint, dust, or lack of lubrication can impede the machine’s performance.

- Solution: Regularly clean your sewing machine, removing lint and dust. Lubricate moving parts as per the manufacturer’s recommendations.

- Fabric Type and Weight:

- Symptom: Different fabrics may require adjustments in tension settings.

- Solution: Tailor your tension settings based on the fabric you are using. Experiment on a fabric scrap before starting your project.

- Bobbin Tension Issues:

- Symptom: Incorrect bobbin tension can lead to loose stitches.

- Solution: Check the bobbin tension, making adjustments as needed. Consult your machine’s manual for guidance on bobbin tension settings.

Troubleshooting Steps:

- Tension Test:

- How: Sew a test fabric swatch with varied tension settings. Observe the stitches on both sides and adjust accordingly until balanced stitches are achieved.

- Thread Re-Thread:

- How: Carefully rethread both the upper thread and the bobbin thread, ensuring proper paths and tension.

- Needle Check:

- How: Inspect the needle for any signs of damage or dullness. Replace the needle if necessary, ensuring it is inserted correctly.

- Bobbin Examination:

- How: Examine the bobbin for even winding and proper insertion. Clear any debris or lint in the bobbin area.

- Machine Lubrication:

- How: Follow the manufacturer’s instructions for machine lubrication, ensuring all moving parts are well-maintained.

Preventive Measures for Future Projects:

- Regular Maintenance Routine:

- Why: Preventive care ensures your sewing machine operates at its best.

- How: Schedule regular cleaning sessions, oiling, and check-ups for your sewing machine. This minimizes the likelihood of loose stitches.

- Quality Threads:

- Why: High-quality threads contribute to stitch consistency.

- How: Invest in threads from reputable brands and match the upper and bobbin threads in terms of type and weight.

- Needle Awareness:

- Why: The right needle is crucial for stitch perfection.

- How: Use the correct needle for your fabric, change it regularly, and ensure it is inserted properly.

- Tension Adjustment Expertise:

- Why: Understanding tension settings enhances your sewing skills.

- How: Familiarize yourself with your machine’s tension adjustments. Practice on scrap fabric to fine-tune tension before starting a project.

Summary: Stitching Success Unleashed

The causes of loose stitches on your sewing machine are like pieces of a puzzle waiting to be solved. Tackling tension, threading, and maintenance with confidence transforms challenges into opportunities for growth. Armed with these insights, you’re not just sewing; you’re orchestrating a symphony of stitches, each one a note in the melody of your creative journey. Happy stitching!

Conclusion

In conclusion, “Sewing Machine Loose Stitches On Bottom” conquering the challenge of sewing machine loose stitches on the bottom demands a careful examination of various factors. Whether it’s adjusting tension settings, using the correct thread, or ensuring proper needle maintenance, resolving this issue often involves a systematic approach.

By understanding the intricacies of your sewing machine and implementing troubleshooting techniques, you can achieve balanced stitches. Remember, regular machine maintenance and thoughtful threading go a long way in preventing the frustration of bottom-side loose stitches, ensuring your sewing projects unfold seamlessly.

FAQs – Sewing Machine Loose Stitches on Bottom:

Q1: Why are my sewing machine stitches loose on the bottom side of the fabric?

A1: Loose stitches on the bottom are often caused by issues with the bobbin, such as improper threading or tension settings.

Q2: Can using the wrong type of thread contribute to loose stitches on the bottom?

A2: Yes, mismatched thread and fabric can lead to tension issues, resulting in loose stitches on the underside.

Q3: What’s the recommended tension setting to prevent loose stitches on the bottom?

A3: Adjust the tension according to your machine’s manual. Experiment with settings until you achieve balanced stitches. “Sewing Machine Loose Stitches On Bottom“

Q4: Should I check the bobbin case for loose threads to fix the issue?

A4: Yes, inspect the bobbin case for any tangled threads or debris that may be affecting the stitching. “Sewing Machine Loose Stitches On Bottom“

Q5: Can a dull or damaged needle cause loose stitches on the bottom of the fabric?

A5: Absolutely, replace the needle regularly, as a dull or damaged one can lead to stitching issues, including loose stitches. “Sewing Machine Loose Stitches On Bottom“

Q6: Is it possible that the bobbin is inserted incorrectly, causing loose stitches?

A6: Correct bobbin insertion is crucial. Follow the machine’s manual for the proper placement to avoid loose stitches. “Sewing Machine Loose Stitches On Bottom“