Navigating the world of industrial sewing machines introduces you to a crucial tool: the Walking Foot Industrial Sewing Machine. This specialized equipment is a game-changer, particularly in projects involving multiple layers or challenging fabrics.

The “What is a Walking Foot Industrial Sewing Machine” guide will delve into its significance, functions, and the unique mechanism that sets it apart. Understanding this powerhouse allows you to seamlessly tackle heavy-duty sewing tasks, ensuring precision, even stitching, and enhanced control, making it an indispensable asset in the realm of professional sewing.

What Is A Walking Foot Industrial Sewing Machine Detailed Answer

A walking foot industrial sewing machine is a powerhouse in the realm of sewing, known for its capability to effortlessly handle heavy-duty fabrics and multiple layers.

Here’s a step-by-step exploration of “What is a Walking Foot Industrial Sewing Machine” what defines a walking foot industrial sewing machine and how to make the most of its unique features.

Step 1: Grasping the Basics

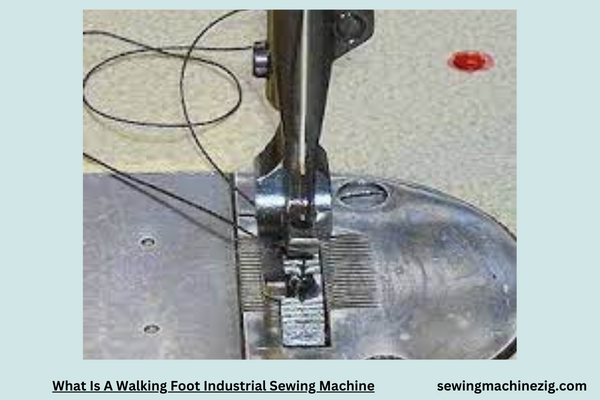

A walking foot industrial sewing machine is distinguished by its walking foot mechanism, which aids in feeding fabric layers uniformly. This prevents shifting and ensures even stitching, making it an ideal choice for tasks that involve thick materials like leather, denim, or quilting projects.

Step 2: Understanding the Walking Foot Mechanism

Unlike traditional sewing machines, a walking foot machine has a built-in feed system on the top of the fabric, complementing the bottom feed from the machine’s feed dogs. This dual-feed system ensures that both the top and bottom layers move together, preventing layers from slipping or stretching during sewing.

Step 3: Installing the Walking Foot

To utilize the walking foot, start by attaching it to your industrial sewing machine. Most machines have a simple mechanism for changing presser feet. Lift the presser foot, release the current foot, and attach the walking foot, ensuring it clicks securely in place.

Step 4: Adjusting Tension Settings

Set your machine’s tension according to the fabric you’re working with. The walking foot ensures that the top and bottom layers are fed consistently, but adjusting tension may be necessary for optimal results, especially with different materials.

Step 5: Choosing the Right Needle

Selecting an appropriate needle is crucial. For heavy fabrics, opt for a needle designed for the material’s thickness. The walking foot, combined with the right needle, prevents skipped stitches and ensures a clean, professional finish.

Step 6: Aligning Fabric Layers

Before sewing, align the fabric layers precisely. The walking foot’s mechanism ensures that both layers are pulled through evenly, reducing the risk of misalignment during stitching.

Step 7: Engaging the Walking Foot

Engage the walking foot by lowering the presser foot lever. This activates the walking foot mechanism, allowing it to move in synchronization with the machine’s feed dogs.

Step 8: Sewing with Confidence

Begin sewing, and you’ll notice the walking foot in action. It moves the top layer of fabric in tandem with the bottom layer, ensuring a smooth and consistent feed. This is particularly advantageous when quilting or sewing bulky fabrics where precise alignment is crucial.

Step 9: Experimenting with Stitch Length

Adjust the stitch length to suit your project. The walking foot accommodates various stitch lengths, providing flexibility for different sewing tasks.

Step 10: Maintenance and Care

Regularly clean and oil your walking foot industrial sewing machine to ensure optimal performance. Consult your machine’s manual for specific maintenance guidelines.

By mastering the usage of a walking foot industrial sewing machine, you unlock the ability to handle diverse fabrics and achieve professional-quality results. Whether you’re a seasoned sewist or just diving into heavy-duty projects, understanding and harnessing the power of the walking foot opens up new dimensions in your sewing endeavors.

What Is A Walking Foot Sewing Machine

A walking foot industrial sewing machine is a specialized tool designed for handling heavy fabrics and multiple layers with ease. Unlike regular sewing machines, a walking foot machine has a unique feeding mechanism that ensures even and consistent fabric movement during stitching.

Key Features:

Walking Foot Mechanism:

- The distinctive feature of a walking foot machine is its walking foot mechanism. This foot, also known as an alternating presser foot, moves in tandem with the feed dogs, gripping and pulling the fabric from the top as well as the bottom.

Ideal for Thick Fabrics:

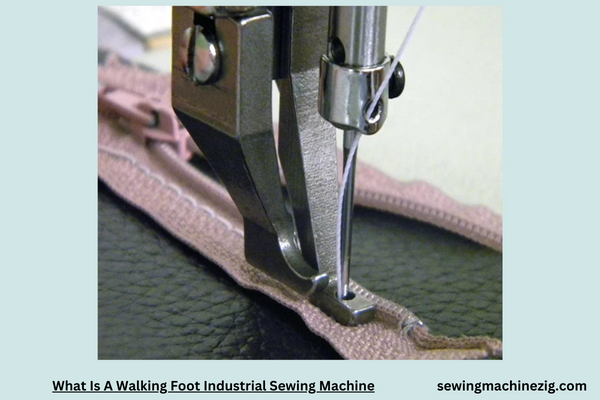

- Walking foot machines excel at sewing through thick and bulky materials, such as leather, canvas, denim, and multiple layers of fabric. The walking foot prevents layers from shifting, resulting in precise and neat stitches.

Layered Fabric Control:

- When dealing with projects that involve quilting or attaching binding to multiple layers, the walking foot ensures that all layers advance together. This eliminates the risk of puckering or misalignment, especially in large and intricate projects.

Versatility in Applications:

- Walking foot industrial machines find applications in various industries, including upholstery, leatherwork, automotive, and quilting. Their ability to handle heavyweight materials makes them a preferred choice for tasks that regular sewing machines may struggle with.

Enhanced Stitch Quality:

- The walking foot ensures that the upper layer of fabric moves in harmony with the lower layers and the machine’s feed dogs. This synchronized movement results in uniform stitch lengths and helps prevent uneven tension in the fabric.

How to Use a Walking Foot Industrial Sewing Machine

- To use a walking foot machine, start by threading the machine and selecting the appropriate needle and thread for your fabric.

- Place your fabric layers under the walking foot and lower the foot using the machine’s lever.

- Engage the walking foot mechanism and begin sewing at a slow and steady pace, allowing the machine to smoothly feed the fabric.

Benefits:

- Precision: Ensures precise stitching, especially in projects involving heavy or slippery materials.

- Reduced Fabric Shifting: Minimizes the risk of layers shifting or uneven sewing, resulting in a professional finish.

- Versatility: Handles a wide range of fabrics and applications, making it a versatile tool for various sewing projects.

In summary, a walking foot industrial sewing machine is a powerful tool designed to tackle challenging sewing tasks with ease. Its unique feeding mechanism makes it a valuable asset for anyone working with heavyweight fabrics or engaging in projects that demand precision and control.

Conclusion

In summary, understanding what a walking foot industrial sewing machine is unlocks a realm of possibilities for tackling challenging projects. With its unique feeding mechanism, this machine excels in handling heavy fabrics and multiple layers, ensuring even and precise stitching.

Whether you’re into upholstery, leatherwork, or quilting, the walking foot’s versatility makes it an indispensable tool. Embrace the enhanced stitch quality and control offered by a walking foot industrial sewing machine, empowering your sewing endeavors with professional results and unmatched efficiency. “What is a Walking Foot Industrial Sewing Machine“

FAQS

Q1: What sets a walking foot industrial sewing machine apart?

A1: A walking foot industrial sewing machine features a unique walking foot mechanism that ensures even fabric feeding. This makes it particularly suitable for handling heavy fabrics, and multiple layers, and preventing fabric shifting during sewing.

Q2: Can I use a walking foot industrial machine for quilting projects?

A2: Yes, a walking foot industrial sewing machine is ideal for quilting. Its consistent fabric feeding and ability to handle thick layers make it well-suited for quilting tasks, ensuring precise and even stitches.

Q3: How does the walking foot mechanism work on an industrial sewing machine?

A3: The walking foot mechanism moves in tandem with the feed dogs, lifting and transporting the fabric layers simultaneously. This prevents uneven feeding, ensuring smooth and controlled stitching, especially on challenging materials. “What is a Walking Foot Industrial Sewing Machine“

Q4: Is a walking foot industrial machine suitable for leatherwork?

A4: Absolutely. The walking foot’s ability to handle heavy materials, like leather, makes it an excellent choice for leatherworking projects. It prevents slipping and ensures accurate stitching on tough materials. “What is a Walking Foot Industrial Sewing Machine“

Q5: Can beginners use a walking foot industrial sewing machine?

A5: While they may seem intimidating, walking foot industrial machines are user-friendly. Beginners can quickly adapt to their operation, especially with proper guidance and practice. “What is a Walking Foot Industrial Sewing Machine“